23T driven sprocket, split sprocket wear-resistant, easy to install, cast PA6 has better wear resistance

Split sprocket has the lowest wear, easy to install, sprocket with protective rim to ensure smooth running of the sprocket, cast

nylon 6 for better wear resistance

Description

What are the components of the non-metal chain plate scraper

1. Helical gear reducer (SEW\NORD\Guomao)

2. NER-720-S (6 inch pitch) chain

3. Glass fiber scraper (standard, high-strength, super-strength three)

4. Wear-resistant boots for upper and lower sides

1. Helical gear reducer (SEW\NORD\Guomao)

2. NER-720-S (6 inch pitch) chain

3. Glass fiber scraper (standard, high-strength, super-strength three)

4. Wear-resistant boots for upper and lower sides

5.NER-720-S traction sprocket

6. NER-NH-78 drive sprocket and driving sprocket

7. High strength stainless steel spindle

8. Cast nylon high strength short shaft

9. Short shaft combination of idle and drive cast nylon

10. Replaceable adjustable balance self-lubricating bearing seat

11. FRP rail and nylon 6 rail bracket

12. High molecular polyethylene (UHMW-PE) track and ground wear strip

6. NER-NH-78 drive sprocket and driving sprocket

7. High strength stainless steel spindle

8. Cast nylon high strength short shaft

9. Short shaft combination of idle and drive cast nylon

10. Replaceable adjustable balance self-lubricating bearing seat

11. FRP rail and nylon 6 rail bracket

12. High molecular polyethylene (UHMW-PE) track and ground wear strip

Features of non-metal chain plate scraper;

1. Good installation quality, easy maintenance and long service life.

2. Energy saving, plastic parts are easy to move, and power consumption is small, generally less than 0.25-0.55KW.

3. The idler (guide wheel) is adjustable for calibration. The length between the chains can also be adjusted according to the chain pitch.

4. The plastic bottom rail scraper can prevent derailment, and general small problems can be adjusted.

5. Low energy consumption and low operating cost.

1. Good installation quality, easy maintenance and long service life.

2. Energy saving, plastic parts are easy to move, and power consumption is small, generally less than 0.25-0.55KW.

3. The idler (guide wheel) is adjustable for calibration. The length between the chains can also be adjusted according to the chain pitch.

4. The plastic bottom rail scraper can prevent derailment, and general small problems can be adjusted.

5. Low energy consumption and low operating cost.

Non-metallic chain plate type mud scraper and its accessories

Serial number |

Name |

Specification |

Product description |

NER-KE8001 |

11 tooth drive sprocket |

Pitch 66.26mm |

Built-in safety bolt, split structure, to protect the equipment from major damage when it fails, an alarm device can be added, and only the sprocket part needs to be replaced when replacing |

NER-KE8002 |

drive chain |

Pitch 66.26mm |

The new pin-wearing method improves the problems of the original cotter pin, which has a large width, is easy to hang dirt, andtakes a long time to rotate and the embossing pin falls off. |

NER-KE8003 |

40 tooth driving sprocket |

Pitch 66.26mm |

Split two-lobe structure, easy to install, the sprocket body and ring gear are assembled separately, and only the ring gear can be replaced for later maintenance, saving costs |

NER-KE8004 |

Bearing housing |

The inner lining is made of polymer material, with good wear resistance, self-lubricating without adding lubricant, only the inner lining can be replaced, saving costs |

|

NER-KE8005 |

23 tooth driven sprocket |

Pitch 152.4mm |

Split sprocket has the lowest wear, easy to install, sprocket with protective rim to ensure smooth running of the sprocket, cast nylon 6 for better wear resistance |

NER-KE8006 |

traction chain |

Pitch 152.4mm |

The product has good wear resistance and is composed of 3 parts. It is easy to install and does not require any tools. The breaking force is greater than 3T. Stainless steel wear-resistant sleeves can be added. |

NER-KE8007 |

FRP scraper |

Material FRP, the scraper is divided into two types: standard type and reinforced type, with high strength, good corrosion resistance of curved type, and two widths of 178 and 138 |

|

NER-KE8008 |

Scraper pads |

Corrosion resistance, increase the screw locking force, and ensure the stable connection of the scraper |

|

NER-KE8009 |

Scraper Connector |

The product has good wear resistance, high strength, and has reinforcing ribs to ensure stable connection |

|

NER-KE80010 |

upper and lower wear boots |

Nylon 6 material, each with two interchangeable working surfaces, one side can be replaced when worn, and the upper wear-resistant shoe has baffles to prevent the scraper from tilting |

|

NER-KE80011 |

Stainless Steel Spindle |

Material stainless steel 304, high strength |

|

NER-KE80012 |

guide |

Material FRP, corrosion resistant and lighter |

|

NER-KE80013 |

Rail bracket |

Made of nylon 6, corrosion-resistant, lightweight |

|

NER-KE80014 |

up and down rails |

Made of ultra-high molecular weight polyethylene, with good self-lubricating wear resistance and corrosion resistance |

|

NER-KE80015 |

Rail washer |

Material 304 stainless steel |

|

NER-KE80016 |

short axis |

Made of cast nylon 6, more corrosion resistant and lighter |

|

NER-KE80017 |

Bushing |

Made of UHMW-PE, more wear-resistant, better self-lubricating, has been replaced to reduce costs |

|

NER-KE80018 |

17 tooth guide sprocket |

Pitch 152.4mm |

Split sprockets have the lowest wear and are easy to install, sprockets with protective rims ensure smooth chain operation, cast nylon 6 for better wear resistance |

NER-KE80019 |

23 tooth drive sprocket |

Pitch 66.26mm reinforced nylon material is suitable for small pools within L20 meters |

|

NER-KE80020 |

Scraper bushing block |

Suitable for 138 width scraper |

|

NER-KE80021 |

big link |

Pitch 152.4, self-locking |

|

NER-KE80022 |

FRP scraper |

imported resin Lightweight FRP Matching rubber strips, abrasion resistant boots |

|

NER-KE80023 |

23 tooth sprocket |

Pitch 152.4mm |

|

NER-KE80024 |

17 tooth sprocket |

Pitch 152.4mm |

|

NER-KE80025 |

11 tooth reducer sprocket |

Pitch 66.26mm |

For replacement and maintenance |

NER-KE80026 |

Tensioner sprocket |

Drive chain tension |

|

NER-KE80027 |

long wear boots |

Wear-resistant nylon length 180mm |

|

NER-KE80028 |

scraper connector small chain |

Pitch 66.26mm |

Slag skimmer for small mud scraper |

NER-KE80029 |

Various nylon ring gears |

Pitch 66.26mm |

Replacement and maintenance use |

NER-KE80030 |

Stainless Steel Chain Wear-resistant Protective Cover |

Trial drive chain 66.26mm and traction chain 152.4mm pitch |

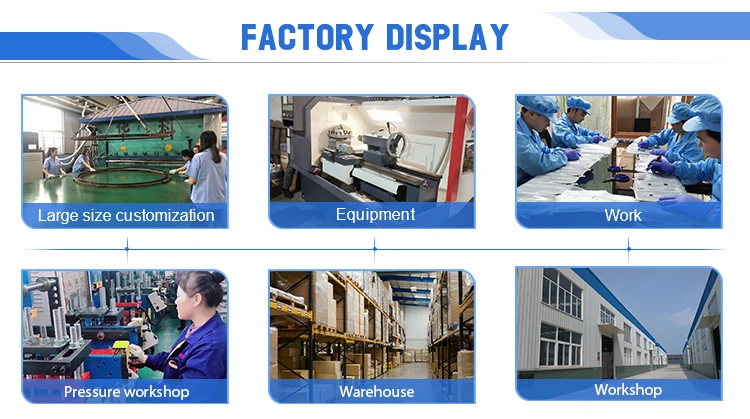

The factory has multiple automatic injection molding machines, so don't worry about large quantities.

If you need custom ones, please let me know the length/height/width of your pool.

Hengshui huake rubber & plastic co.,LTD.Is a comprehensive enterprise that introducesforeign advanced technology, integrates development,design, manufacturing and processing. The company is committed to the r&d and production of high performance products of newrubber and plastic materials supporting equipment in the new energy photovoltaic andenvironmental protection water treatment industry. The company has passed iso9001-2008product quality certification and registered brand "NER" in the spirit of improving productquality and building a first-class brand,providing high-quality products and the mosthumanized services for customers. Focus on the research and development of application technology in synthetic rubber industry. The factory has established a set of rubber vulcanization curve control system and introduced the production and testing equipment of rubber products. Under the complex and rigorous control mechanism and the application of advanced production, management and testing technology, it has achieved the consistency of all product processes, that is, product design, formula development, raw material mixing, mold processing, inspection, performance test, manufacturing, etc. The organic combination of rubber product manufacturing and rubber raw material formula development has laid a solid foundation for the company in innovative design and market development. It has obtained a number of patent certificates in terms of new structure sealing ring and product production process. The company takes innovative technology and meeting user needs as its business philosophy, makes every effort to build ner brand, and provides reasonable and advanced solutions for many supporting manufacturers of industrial enterprises. This relationship ensures the high-quality products of the original design manufacturer (ODM) and contributes to the company's technical background for future development planning. This cooperation enables the original manufacturer (ODM) and the company to obtain continuous competitive advantages. Today, NER has become a rubber component supplier with certain competitive advantages in the global rubber market. Its products are mainly used in fluid sealing equipment in sewage treatment, automobile, aviation, machinery, petrochemical, medical treatment, food, electronics, national defense, military and other industries.

Q1: Are you a factory or a trader?

A: We are a manufacturer in the rubber and plastic industry for 15 years.

Q2: Can your company customize all kinds of rubber parts?

A: Yes, our company can process (OEM) flat pads without opening molds.

Q3: Does your company produce both nylon and plastic parts?

A: Yes, we have CNC machining workshop and produce nylon and plastic.

Q4: How long is your usual delivery date?

A: Spot goods can be delivered on the same day, and customized products can take 7-10 working days.