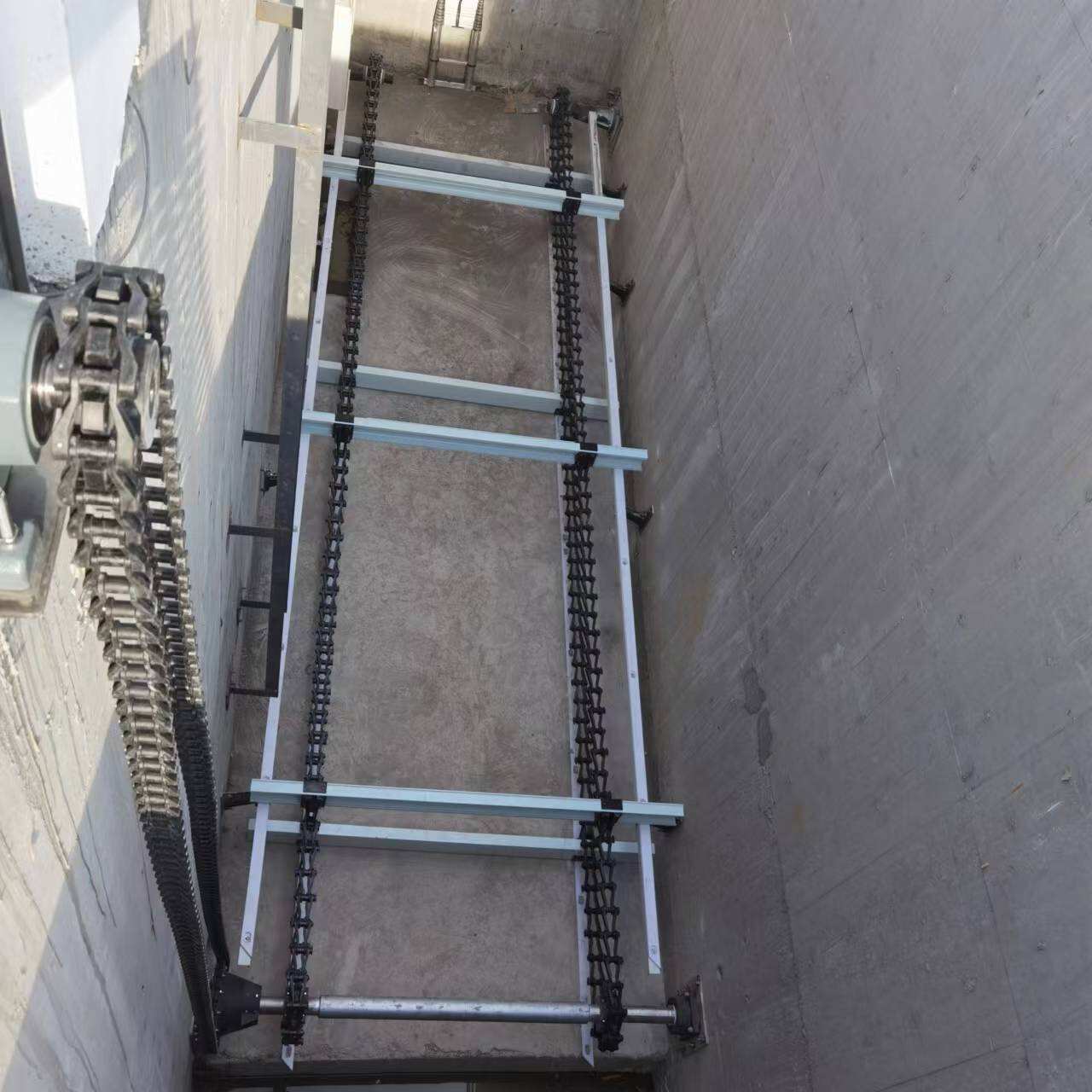

While the term "pool cleaning" often brings to mind manual tools for swimming pools, in an industrial water and wastewater context, it refers to the mechanical cleaning of large-scale process basins or "pools," such as those found in water treatment plants, effluent holding ponds, or industrial process tanks. A pool cleaning plastic scraper for these applications is a robust, engineered system designed for the continuous or intermittent removal of settled solids from the bottom of these large structures. The challenges in these environments can include exposure to chemicals, algae, and abrasive sediments. Using plastic—specifically high-performance polymers like HDPE or UHMW-PE—for the scraper components provides significant advantages over metal. It eliminates corrosion entirely, a critical benefit in chemically treated water or where disinfectants like chlorine are used. The plastic's natural lubricity and abrasion resistance allow it to move solids effectively without wearing quickly against the tank floor. These scrapers can be designed in various configurations, such as reciprocating systems for rectangular basins or rotary systems for circular tanks, and can be equipped with blades, squeegees, or brushes depending on the type of material being collected. Our manufacturing capability extends into this area. We engineer plastic scraper systems for industrial pool and tank cleaning applications. Our designs prioritize effective solids removal, operational reliability, and minimal long-term maintenance. By utilizing corrosion-resistant polymers, we ensure the system's longevity even in challenging environments, providing a cost-effective and "fit-and-forget" solution for maintaining the efficiency and cleanliness of large process basins. For inquiries regarding custom-designed plastic scrapers for industrial pool cleaning applications, please contact us to discuss your specific requirements.