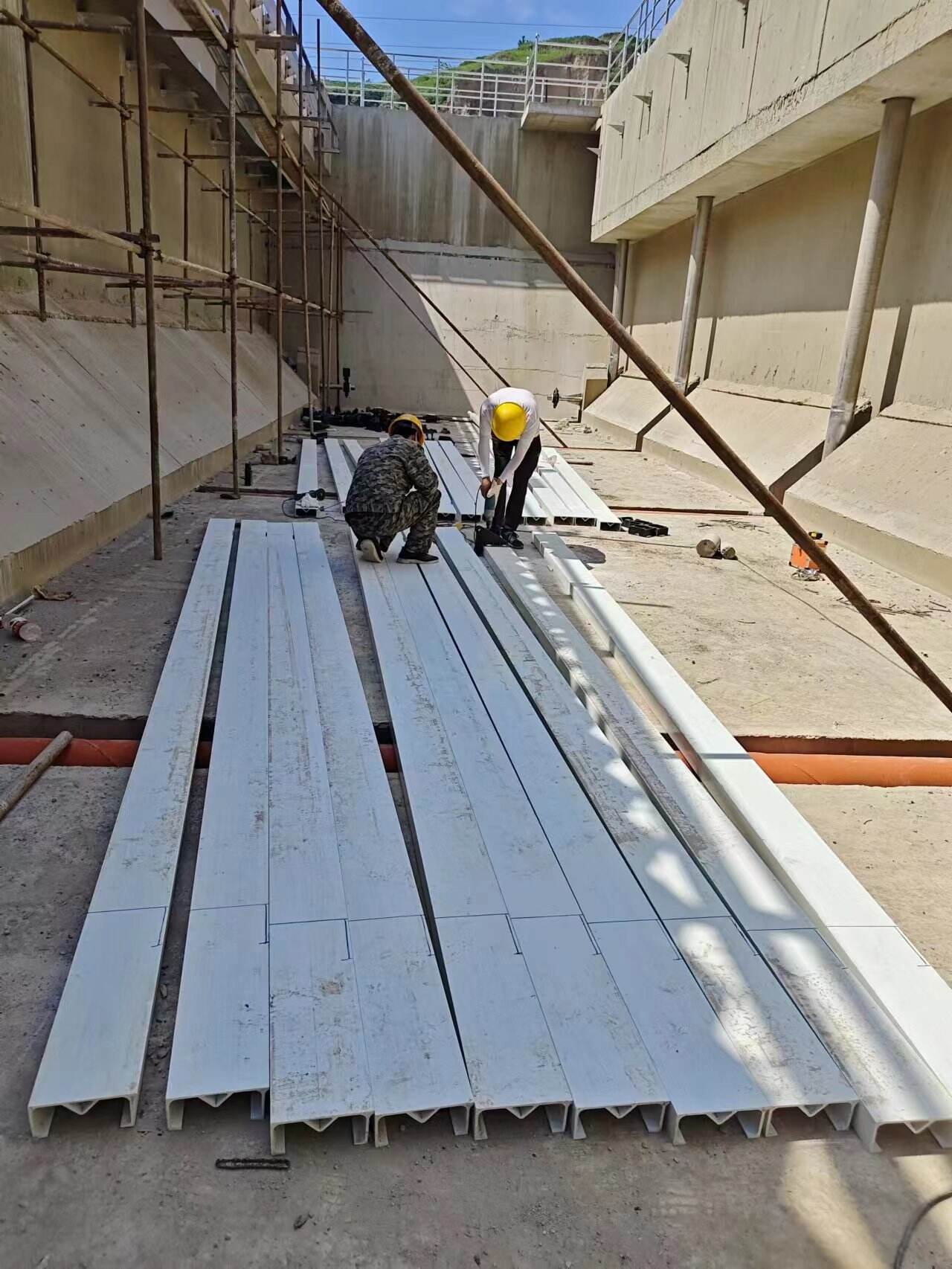

Inženiertehnisko plastmasu dūņu skrāpis ir augstas veiktspējas komponents, kas izceļas ar modernu termoplastu, nevis standarta plastmasas izmantošanu. Inženiertehniskās plastmasas, piemēram, UHMW-PE (īpaši augstas molekulmasas polietilēns), HDPE (augsta blīvuma polietilēns), PVDF (polivinilidēnfluorīds) un neilons, raksturo to pārākās mehāniskās, termiskās un ķīmiskās īpašības salīdzinājumā ar standarta plastmasām. Piemēram, UHMW-PE piedāvā izcilu augstas triecienizturības, ārkārtīgi zemas berzes, izcilas nodilumizturības un labas ķīmiskās izturības kombināciju. Tas padara to par ideālu materiālu skrāpju asmeņiem un nodiluma detaļām. Konkrētas inženiertehniskās plastmasas izvēle ir aprēķināts lēmums, kas balstīts uz īpašajām pielietojuma prasībām: ķīmisko iedarbību, darba temperatūru, dūņu abrazīvitāti un mehāniskās slodzes prasībām. Šī materiālzinātnes vadītā pieeja nodrošina, ka skrāpis nav vienkārši "izgatavots no plastmasas", bet gan optimāli konstruēts no materiāla, kas nodrošinās maksimālu veiktspēju un ilgmūžību konkrētā skarbajā vidē. Rezultāts ir produkts, kas nodrošina nepārspējamu ekspluatācijas priekšrocību: nepārspējamu izturību, minimālu apkopi un augstu dūņu noņemšanas efektivitāti. Mūsu kompetence ir pareizās inženiertehniskās plastmasas izvēle un pēc tam precīza skrāpju sistēmas ražošana ar visaugstākajām pielaidēm, nodrošinot, ka tā darbojas kā kritiski svarīgs elements attīrīšanas procesā. Lai saņemtu norādījumus par optimālo inženiertehnisko plastmasu atbilstoši jūsu dūņu īpašībām, lūdzu, sazinieties ar mūsu materiālu ekspertiem.