Years of

Experience

Hengshui Huake Rubber & Plastic Co., Ltd. is a comprehensive enterprise integrating the introduction of foreign advanced technology, development, design, manufacturing and processing.

The company is committed to new energy photovoltaic, environmental protection water treatment industry equipment supporting rubber and plastic new material research and development and production of high-performance products, the company through IS09001-2008 product quality certification, registered brand "NER" in the spirit of improving product quality, to create a first-class brand concept, to provide our customers with high quality products and the most humane service.

M floor area

Containers shipped out annually

Years Professional factory

Countries covered by products

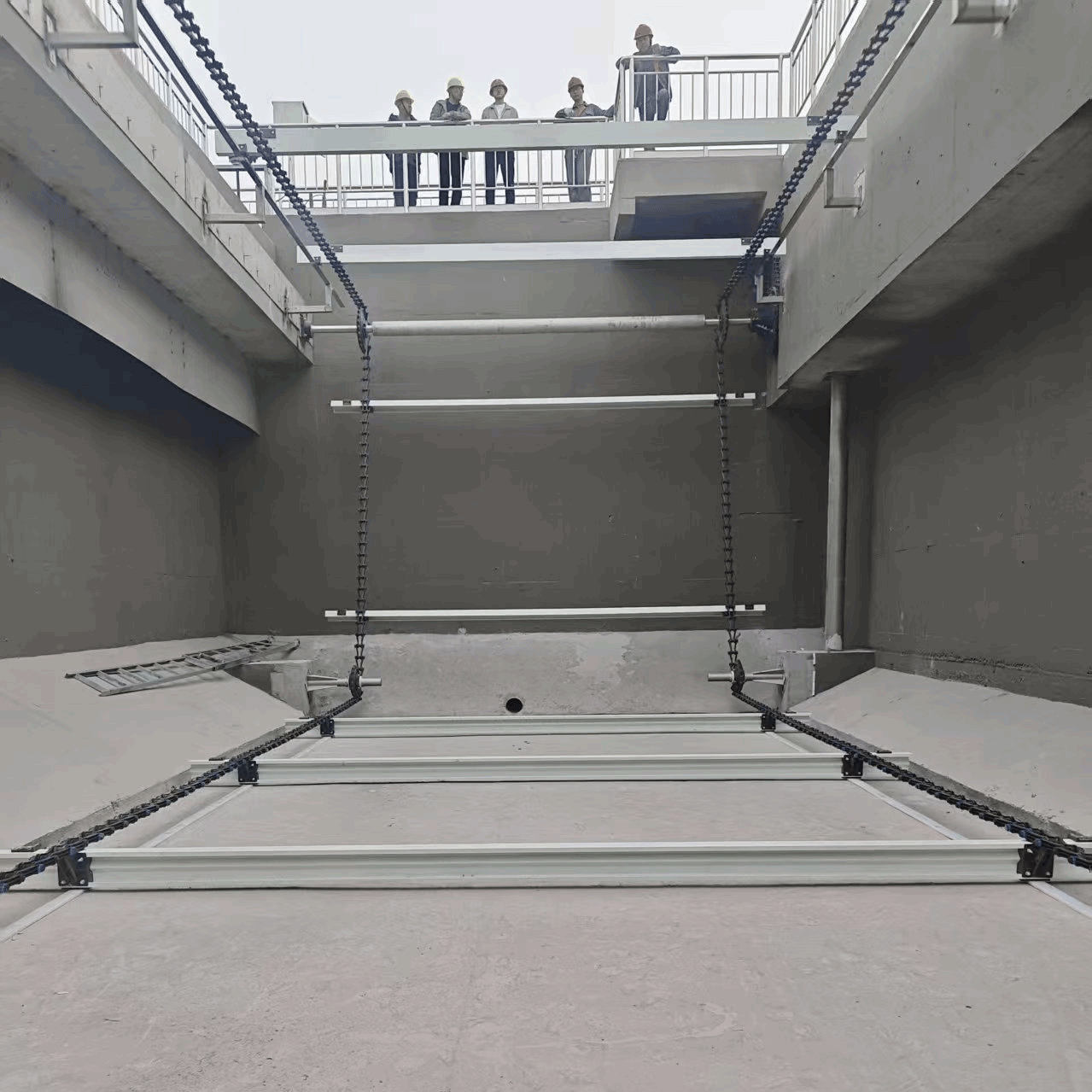

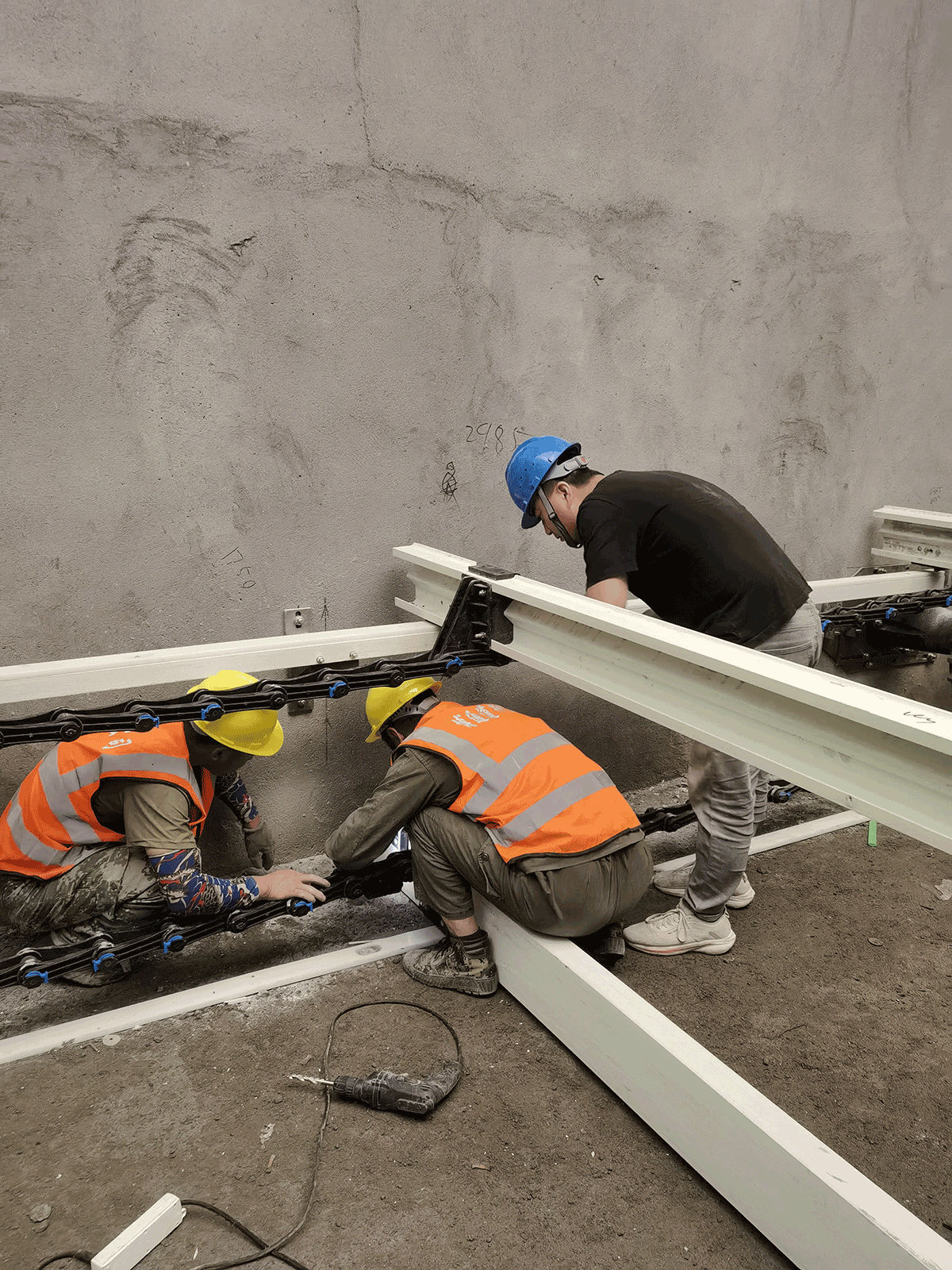

Focus on the development and manufacturing of non-metal rectangular pool sludge scraper, with innovative technology to provide efficient, corrosion-resistant, lightweight sludge scraping solutions for the sewage treatment industry.

1 2 3 4 5

1 2 3 4 5

Say goodbye to metal corrosion with high-strength composite materials/engineering plastics, offering acid and alkali resistance, anti-aging properties, and a lifespan extended by 3 times or more.

Lightweight design reduces installation and maintenance effort by 30% and lowers energy consumption by 20%.

Modular structure supports customizable dimensions.

Widely applicable across industries: municipal sewage/chemical wastewater/food processing/new energy sectors.

2-year extended warranty/lifetime technical support/24-hour emergency response.

The non-metal chain sludge scraping system is used in the primary sedimentation tank, secondary sedimentation tank and high efficiency sedimentation tank of the sewage treatment plant. The function is to separate the mud and water, and to clarify, concentrate and return the activated sludge.

Precise Sludge Scraping Mechanism: Our sedimentation tank sludge scrapers are equipped with a precise sludge scraping mechanism. It can accurately control the scraping depth and speed, adapt to different sludge thicknesses and sedimentation conditions, efficiently and thoroughly remove sludge, and improve the efficiency of sewage treatment.

Our rich experience in wastewater treatment and advanced facilities ensure high - standard sedimentation tank sludge scrapers. With numerous successful cases, we prove our reliability. Contact our pros to get the best solution for your wastewater treatment needs.

With 18 years of deep immersion in the industry, we have amassed a wealth of production experience. We are well - versed in various product processes, capable of accurately solving production issues and ensuring the smooth and stable operation of the production process.

We concentrate on customized products and delve deep into customers' needs. Every link from design to production can be adjusted according to requirements. We offer personalized solutions to meet diverse demands.

We have established a comprehensive quality management system. Every process, from raw material procurement to finished product delivery, is strictly inspected. With exquisite craftsmanship, we create high - quality products and earn the trust of our customers.

Equipped with a professional after - sales team, we provide comprehensive services. We respond promptly to customers' feedback and timely solve product - usage problems, ensuring worry - free cooperation.

Stay up to date with the latest news and events at Company by checking out our news section, where you can find valuable insights, industry trends, and exciting updates on our products and services.

In the current sewage treatment field, the sedimentation tank sludge scraper, as a key piece of equipment, its technological innovation is of vital importance to the development of the industry. Recently, the sedimentation tank sludge scraper industr...

Recently, a highly innovative new non - metal chain plate sludge scraper has drawn extensive attention in the field of environmental protection equipment. With the continuous growth and upgrading of sewage treatment demands, the emergence of this slu...

Lubricate Components: Inject an appropriate amount of lubricating oil and grease into all drive structures, reducers, drive chains, rolling bearings, and moving parts to ensure the smooth operation of the equipment. Power Supply Check: After co...

Why plastic scrapers cut annual repair costs by 45% and extend service life to 5–7 years. Corrosion-resistant HDPE, PU & modular IoT-ready designs—get the data-backed ROI.

Discover why nonmetallic flying scrapers resist corrosion 90% better than metal, cut maintenance by 63%, and save 60% in lifecycle costs. Ideal for high-sulfide wastewater treatment. Learn more.

Discover why material choice matters in corrosive environments. Compare 316L stainless steel vs GRP mud scrapers for longevity, cost, and performance. Get the full analysis.

Struggling with scraper failure in acidic wastewater tanks? Discover how GRP and duplex stainless steel scrapers reduce maintenance by up to 87%. Get the full lifecycle cost analysis and selection guide.