The main features of the non-metallic sludge scraper

1. Strong corrosion resistance

It adopts non-metallic materials such as engineering plastics (such as PP, PE, POM) or fiberglass reinforced plastic (FRP), which can resist corrosive substances such as acids, alkalis, salts and organic matter in sewage, thus extending the service life of the equipment.

It is suitable for highly corrosive environments such as chemical wastewater, electroplating wastewater, and seawater desalination.

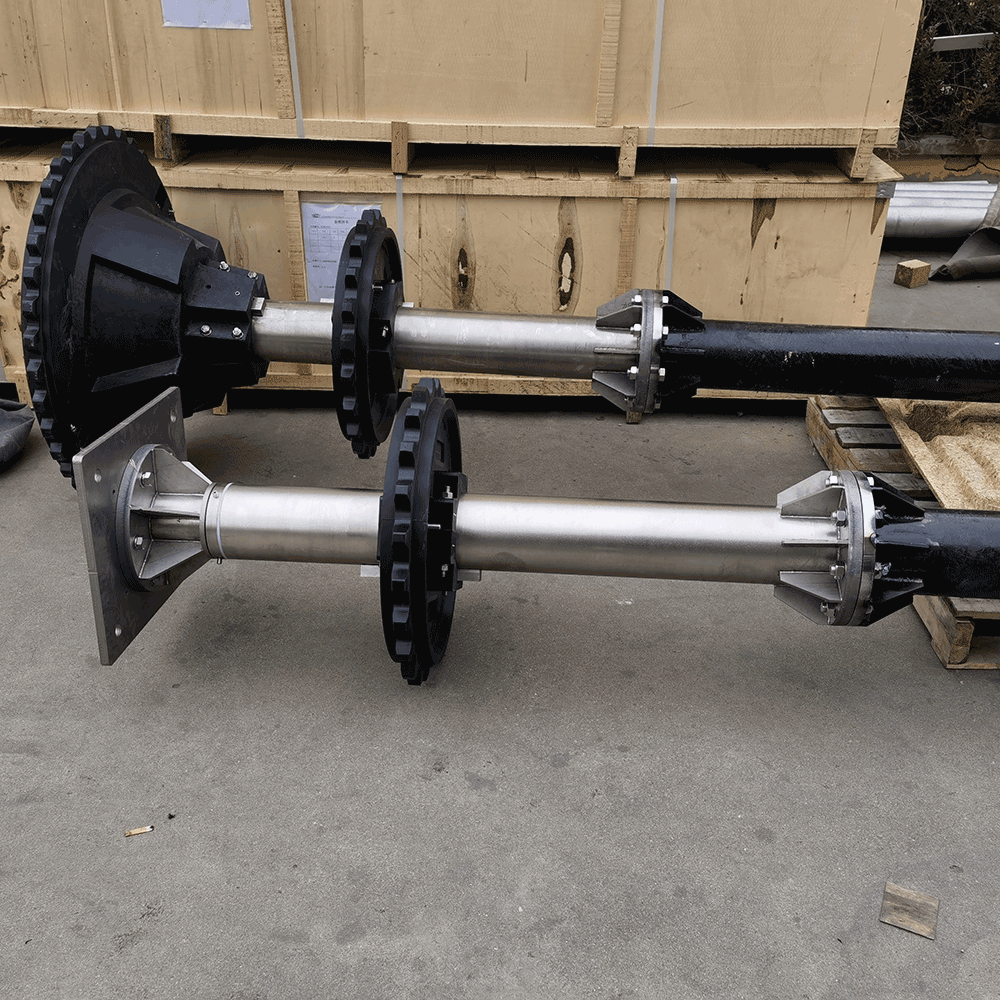

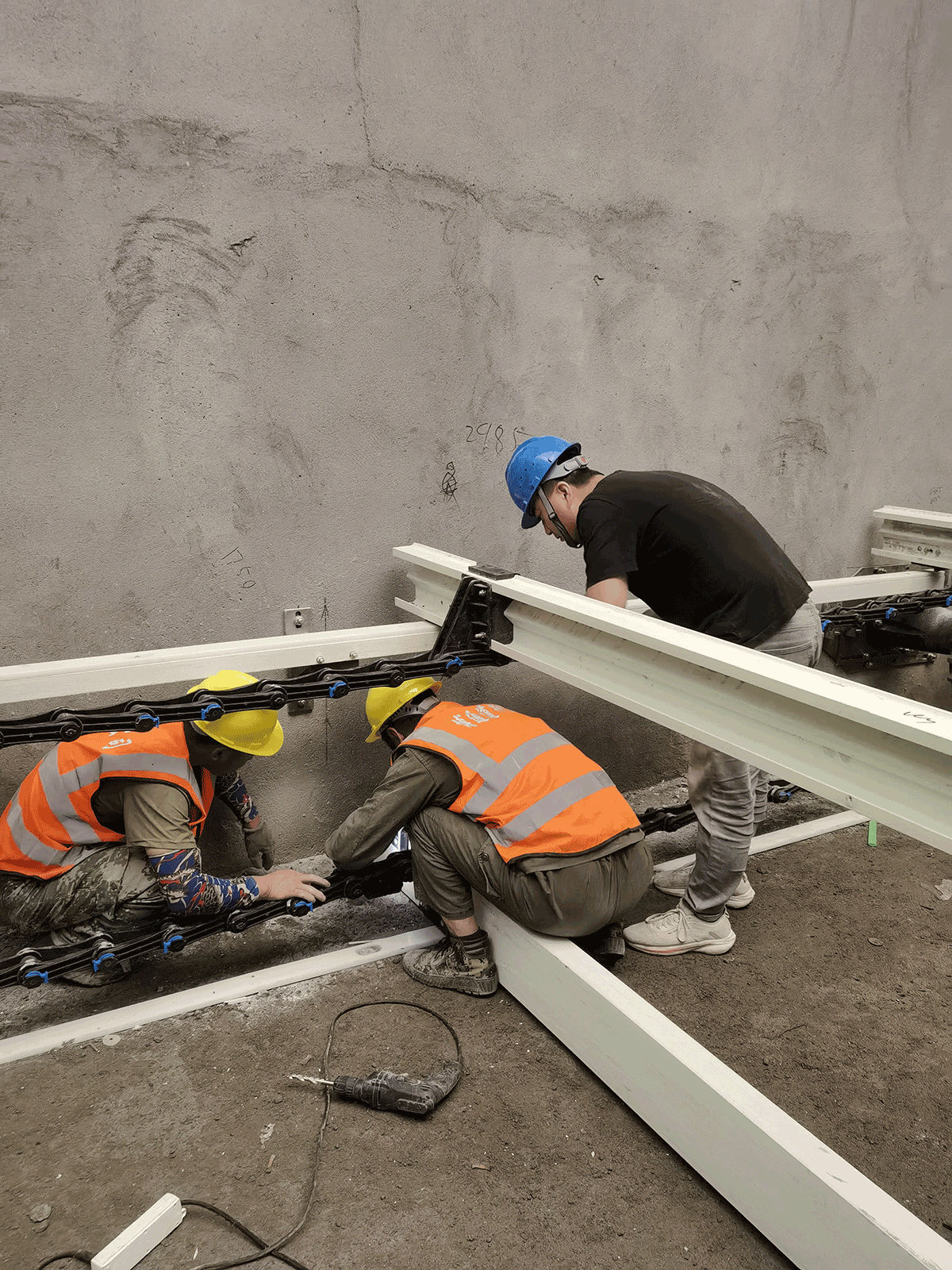

2. Lightweight design

The density of non-metallic materials is much lower than that of metals (such as steel), the overall weight of the equipment is light, installation and transportation are more convenient, and the requirements for the load-bearing capacity of the pool structure are lower.

3. Good anti-scaling performance

The non-metallic surface is smooth, making it difficult for sludge to adhere, reducing the resistance of sludge scraping, lowering energy consumption, and simultaneously reducing the frequency of manual cleaning.

4. Low maintenance cost

It does not require frequent anti-corrosion treatments (such as painting and galvanizing) like metal sludge scrapers, is easy to maintain and has a lower long-term usage cost.

5. Environmental protection and recyclability

Non-metallic materials can be recycled, which is in line with the concept of green environmental protection and reduces pollution to the environment.

6. Adapt to complex water quality

It has strong adaptability to oily, fibrous or high-viscosity sludge and is less likely to fail due to corrosion or wear.