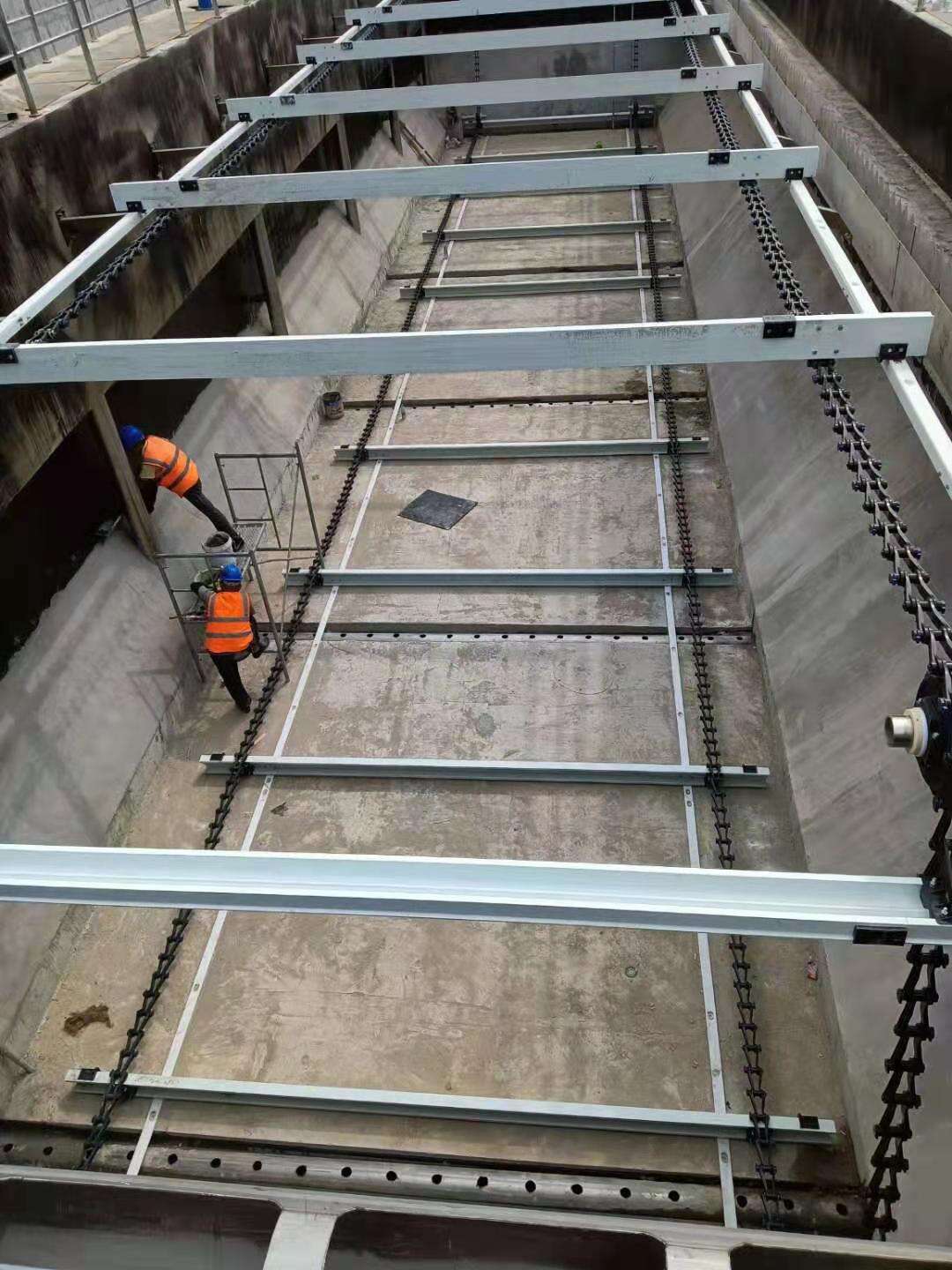

An STP (Sewage Treatment Plant) is a facility designed to treat wastewater generated from residential, commercial, and institutional sources. The acronym STP is commonly used in project specifications, tenders, and technical discussions to denote the complete installation. The standard treatment sequence involves screening, grit removal, primary sedimentation, biological treatment (e.g., activated sludge, MBBR, SBR), secondary sedimentation, and disinfection. The primary sedimentation tank (or primary clarifier) is a workhorse unit where a significant portion of suspended solids is removed by gravity. The mechanical system responsible for continuously collecting these settled solids is the sludge scraper. The longevity and reliability of this scraper are paramount for the STP's uninterrupted operation. Huake's core expertise is providing the optimal solution for this application: non-metallic sludge scrapers. These scrapers are fabricated from composite materials that are completely inert to the corrosive gases (e.g., hydrogen sulfide) and liquids present in raw sewage. This inherent resistance eliminates the common failure mode of corrosion, ensuring the scraper system operates reliably for decades with minimal maintenance. For any STP, from a compact package unit to a large municipal facility, integrating Huake's technology secures the primary treatment process, ensuring consistent performance, reducing operational costs, and forming a stable foundation for the biological treatment stages that follow.