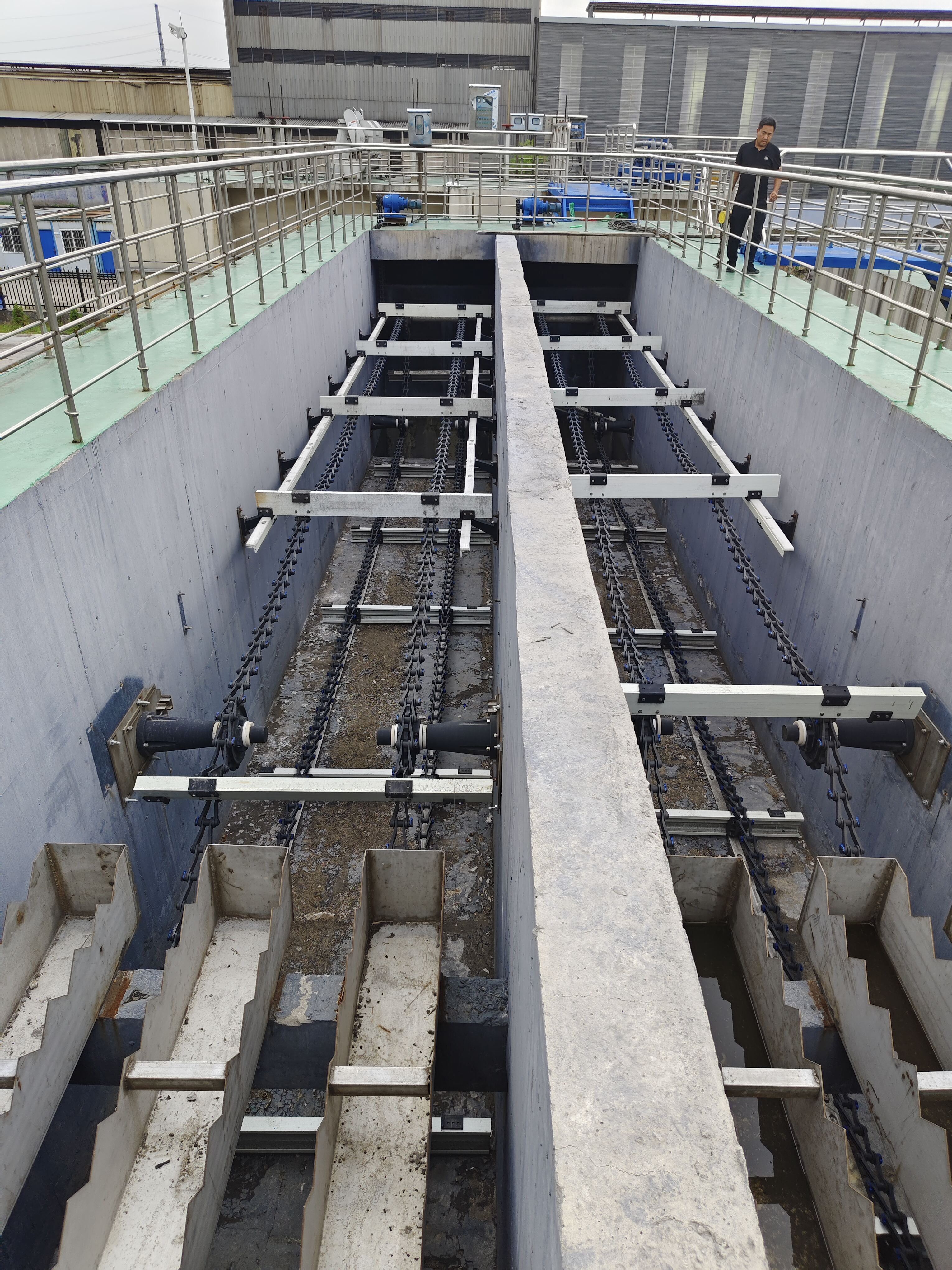

A flying scraper is a pivotal piece of mechanical equipment utilized in rectangular sedimentation tanks and clarifiers within water and wastewater treatment plants. Its primary function is the continuous collection and conveyance of settled sludge from the tank floor to a designated sludge hopper for subsequent removal and processing. The term "flying" denotes that the scraper mechanism is typically mounted on a bridge or carriage that moves along the length of the tank on rails or wheels, as opposed to being fixed. The core assembly includes a drive unit, a traction system (often using chains or steel cables), and a series of scraping blades or flights that are dragged along the bottom. The design is meticulously calculated to ensure even contact with the tank floor to prevent sludge bypass and buildup. Operation is typically bidirectional; the scraper moves forward to collect sludge and then lifts slightly or returns on a faster cycle to reset its position. This equipment is critical for maintaining the hydraulic capacity and treatment efficiency of the sedimentation basin. If sludge is not removed promptly, it can become septic, release gases that resettle solids, and ultimately reduce the effective volume of the tank, compromising effluent quality. Flying scrapers are valued for their reliability, simplicity of operation, and effectiveness across a wide range of tank sizes and sludge types. They are a fundamental component in both municipal sewage works and industrial pretreatment facilities. The specific configuration, including size, power, and material of construction, varies significantly based on application. To determine the optimal flying scraper configuration for your sedimentation tank's dimensions and duty cycle, we recommend contacting our technical support team for a detailed discussion and a customized solution proposal.