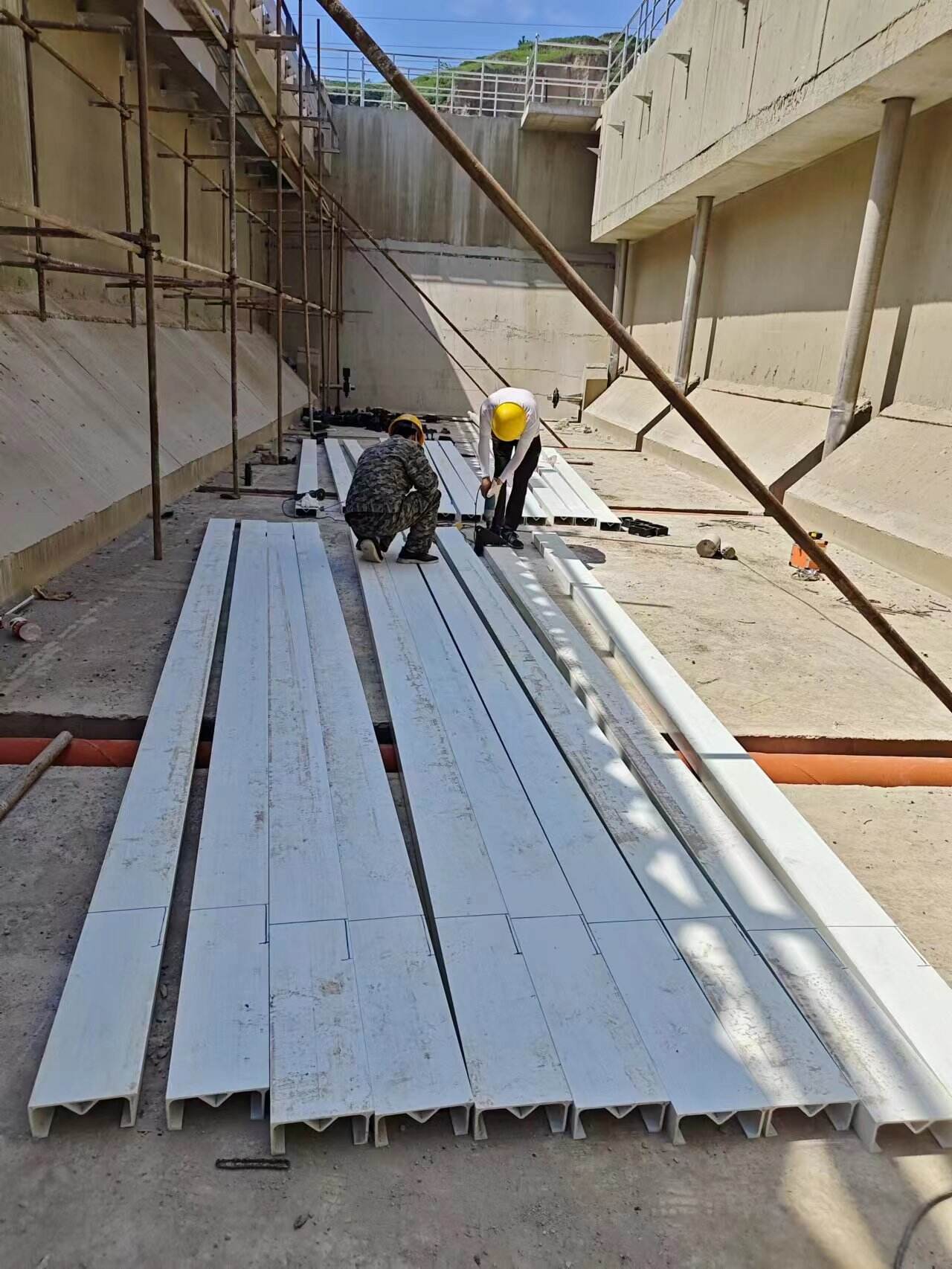

Our Pool Flying Scraper Installation Service provides a seamless, turnkey solution from equipment delivery to final commissioning, ensuring your new scraper system is operational correctly and efficiently from day one. Our team of experienced field technicians manages the entire process: unloading and staging components, assembling the structure, installing the drive unit and scraper assembly, performing precise alignment checks, and connecting electrical power and controls. We rigorously test the installation under load to verify smooth operation, proper clearance, and correct alignment with the sludge hopper. This professional service is invaluable for several reasons: it eliminates the need for your plant to allocate scarce internal resources, it ensures the installation is performed to manufacturer specifications (protecting your warranty), and it drastically reduces the risk of future operational issues caused by improper setup. For complex or large-scale projects, such as installing a scraper in a diameter tank over 40 meters, our certified installation team has the specialized tools and expertise to complete the job safely and on schedule. We also provide comprehensive documentation upon completion, including as-built drawings and operational manuals. By opting for our professional installation service, you invest in the long-term reliability and performance of your critical sedimentation equipment. Contact our project management department to schedule an installation and receive a detailed service quote.