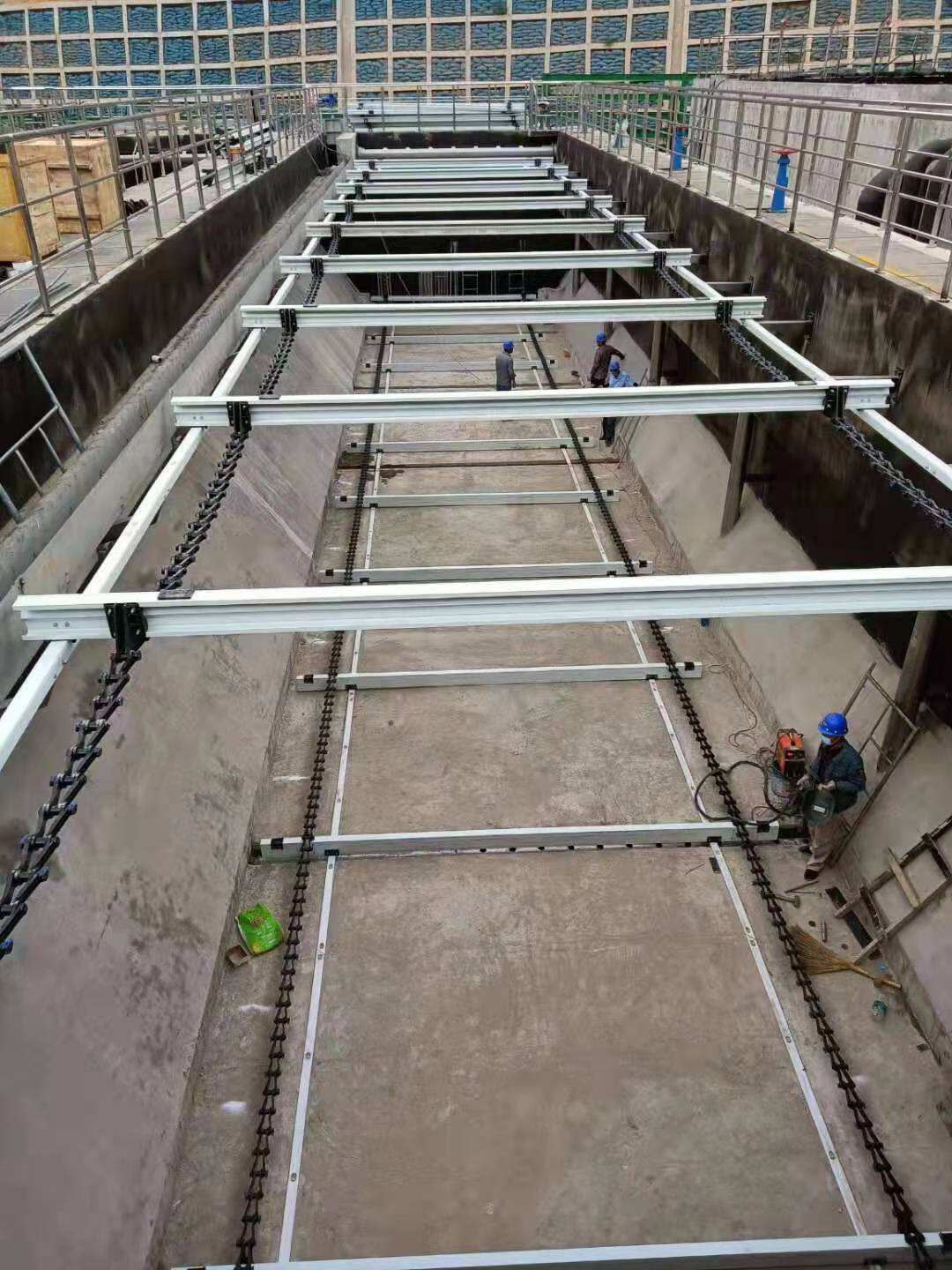

Corrosion resistant sewage treatment equipment is essential for ensuring the longevity and reliability of any wastewater facility. The operating environment is inherently aggressive, featuring moisture, acidic conditions, hydrogen sulfide gas, and various other chemicals that rapidly degrade conventional materials. Equipment failure due to corrosion leads to frequent downtime, high maintenance costs, and process inefficiencies. Huake is a dedicated manufacturer of this specific type of equipment, focusing on the critical sludge scraping systems for sedimentation tanks. Huake's entire product line is engineered around the principle of maximum corrosion resistance. By utilizing non-metallic composite materials, their scrapers, blades, and components are completely immune to rust and electrochemical corrosion. This fundamental property ensures that the equipment maintains its structural integrity and functional performance over an exceptionally long service life, even when continuously submerged in the most challenging wastewater. Investing in Huake's corrosion-resistant equipment is a proactive strategy to eliminate one of the most common and costly failure modes in a treatment plant. It transforms the sedimentation tank from a high-maintenance liability into a reliably operating asset, significantly reducing the total cost of ownership and contributing to the overall stability and efficiency of the treatment process.