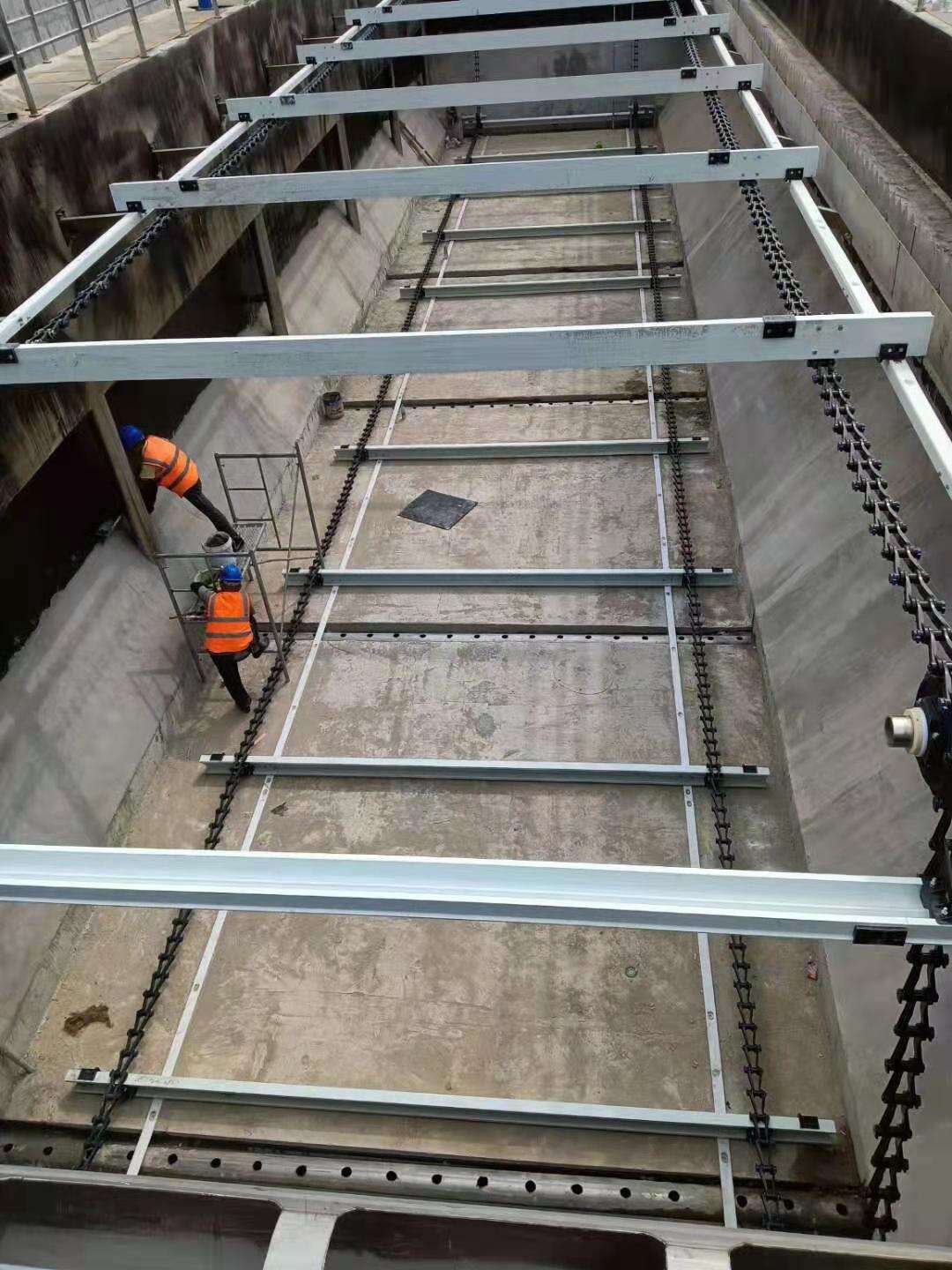

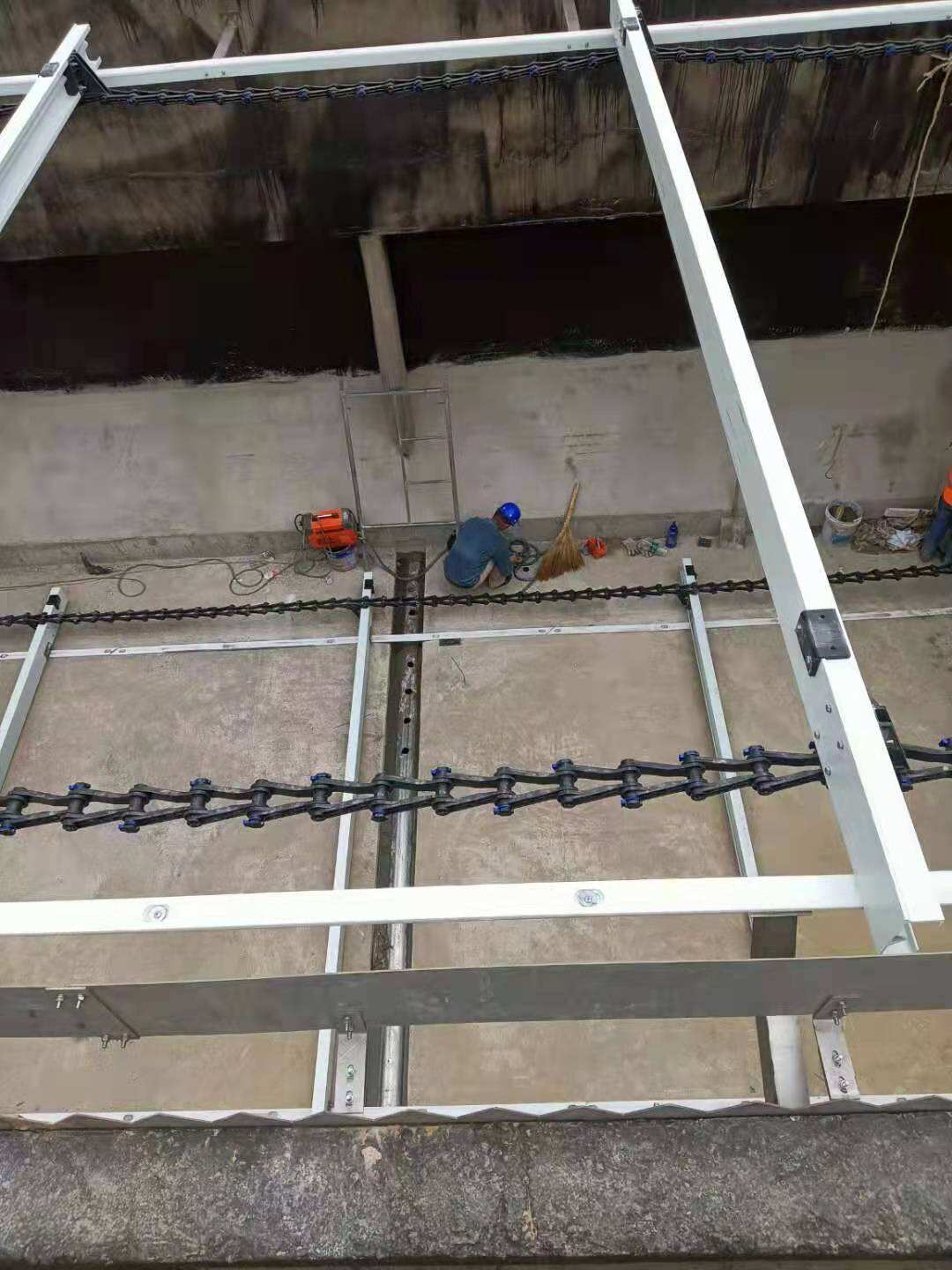

An efficient sludge handling sewage treatment plant focuses on optimizing the entire process of solids management, from separation and thickening to digestion and dewatering. The goal is to minimize the volume and weight of final sludge for disposal while maximizing resource recovery (e.g., biogas) and reducing associated costs. Efficiency begins at the very first step: primary sedimentation. An effective scraper system here is crucial for efficiently concentrating raw sludge. Huake's non-metallic sludge scrapers are designed for this precise purpose. Their robust design ensures continuous and complete collection of settled solids from the entire tank floor. There is no short-circuiting or missed areas that can lead to sludge buildup and eventual septic conditions, which reduce treatment efficiency and increase odor problems. By promptly and reliably moving sludge to the collection hopper, Huake scrapers ensure that the sludge withdrawn is at its highest possible concentration. This directly increases the efficiency of downstream sludge thickeners and digesters, reducing the volume of water that needs to be processed and transported. In a plant prioritizing efficient sludge handling, this reliable first step is invaluable. It sets the stage for an optimized overall process, leading to lower energy consumption for pumping and mixing, reduced chemical usage in conditioning, and lower costs for transportation and final disposal of biosolids.