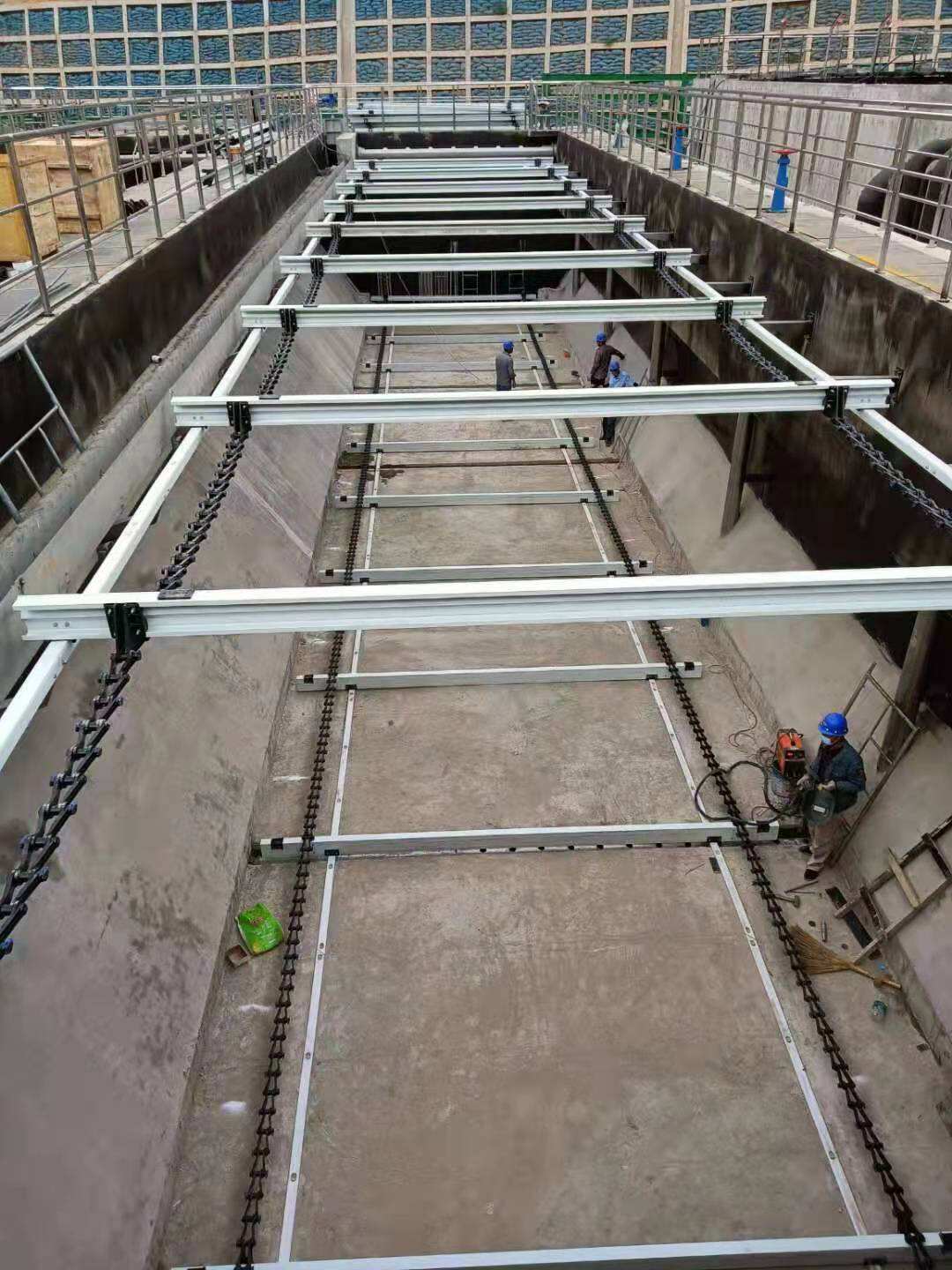

An industrial zone sewage treatment plant, or common effluent treatment plant (CETP), receives and treats wastewater from multiple factories within an industrial estate. This wastewater is incredibly diverse and often more challenging than municipal sewage due to the potential mixture of chemicals, heavy metals, solvents, and high-strength organic waste from various industries like textiles, food processing, pharmaceuticals, and engineering. The treatment process must be robust and flexible to handle fluctuating loads and compositions. Primary sedimentation is a critical first step for removing settleable solids and associated pollutants. The equipment in this stage must be built to withstand an extremely aggressive and unpredictable chemical environment. Huake's non-metallic sludge scrapers are specifically engineered for this challenge. Their complete immunity to corrosion ensures continuous, reliable operation where traditional metal scrapers would rapidly fail. This reliability is non-negotiable for a CETP, as a breakdown in primary treatment could send a shock load of solids and toxins into the biological treatment stage, causing widespread process failure and potential violations of the plant's strict discharge permit. By installing Huake scrapers, the CETP management guarantees a stable and maintenance-free primary sedimentation process. This forms a solid foundation for the entire treatment train, enabling consistent effluent quality despite the variable and complex nature of the incoming wastewater from the diverse industrial tenants, thereby ensuring the zone's environmental compliance and sustainability.