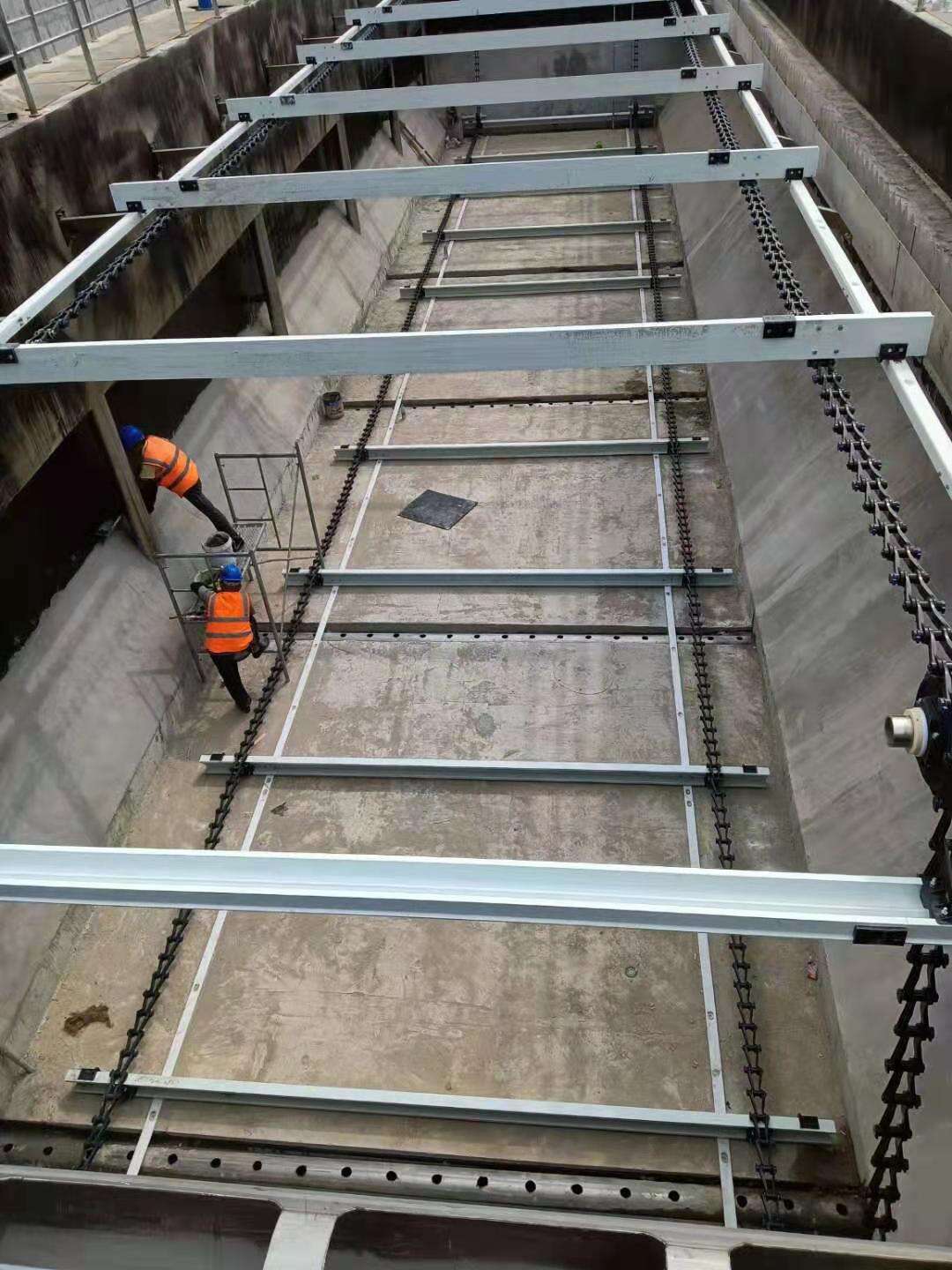

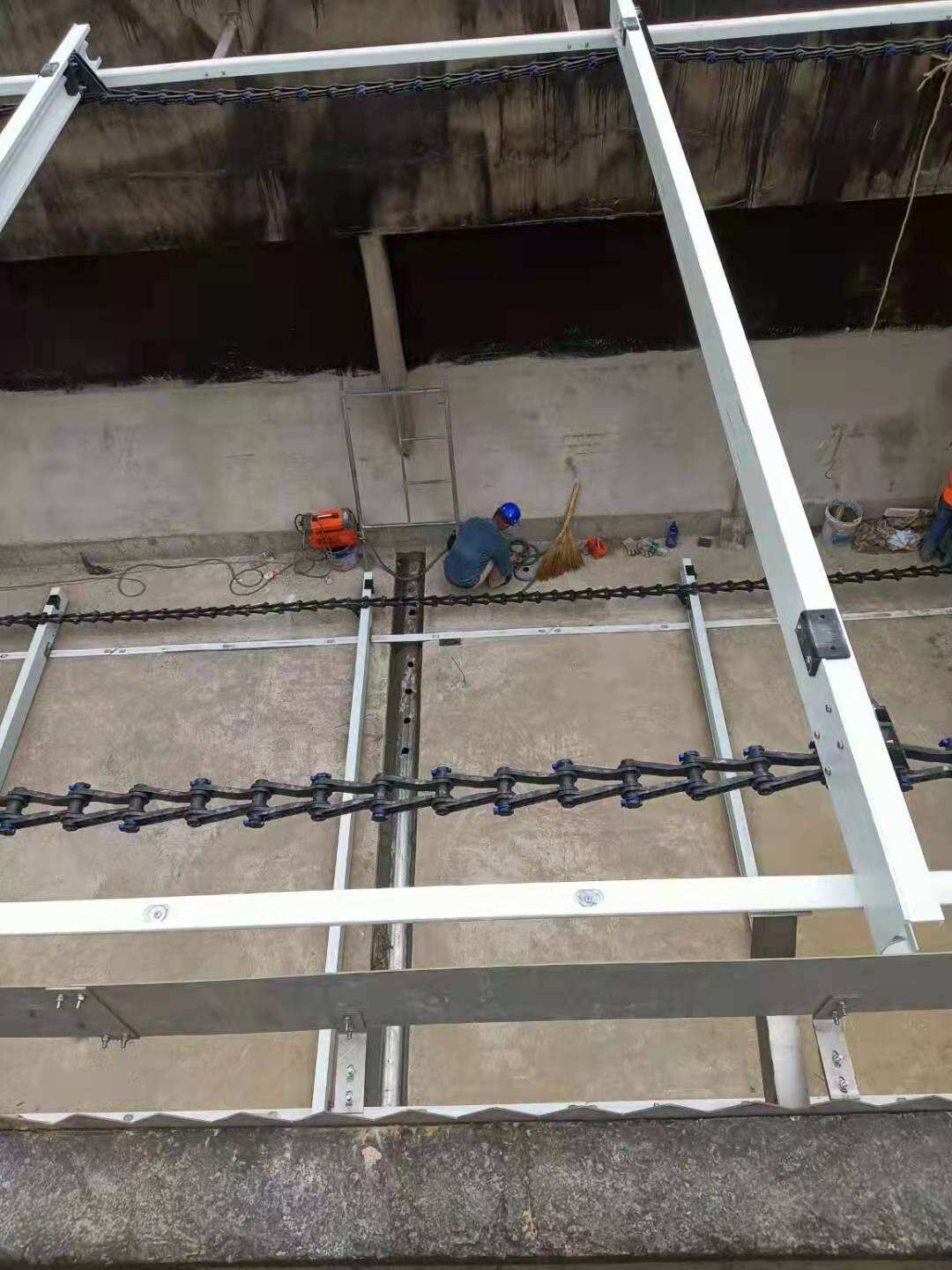

An ecological park sewage treatment plant is designed not only to treat wastewater but to do so in a way that minimizes its environmental footprint, often integrating natural elements and aiming for harmony with the surrounding parkland. These facilities may utilize constructed wetlands, lagoons, or other natural treatment processes alongside conventional mechanical systems. The treatment goal is typically to produce high-quality effluent suitable for replenishing park water features, irrigation, or creating wildlife habitats. Even in these "green" settings, mechanical components like sludge scrapers in sedimentation tanks are often necessary for compactness and efficiency. For such an application, equipment must be exceptionally reliable and low-maintenance to avoid disrupting the park's aesthetic and recreational value with frequent repairs. Huake's non-metallic sludge scrapers are an ideal fit. Their corrosion-resistant nature means they can handle wastewater without degrading, and their long service life ensures minimal intrusive maintenance activities within the park. The scrapers operate quietly and efficiently, maintaining the tranquility of the environment. In a specific case, an ecological park treating restroom wastewater and runoff would use a primary clarifier equipped with a Huake scraper to remove solids reliably. This ensures the downstream natural filtration systems, like wetlands, are not clogged with excess sludge, allowing them to function optimally for polishing the water. This synergy between reliable mechanical pretreatment and natural treatment processes is key to the sustainable operation of an ecological park's water management system.