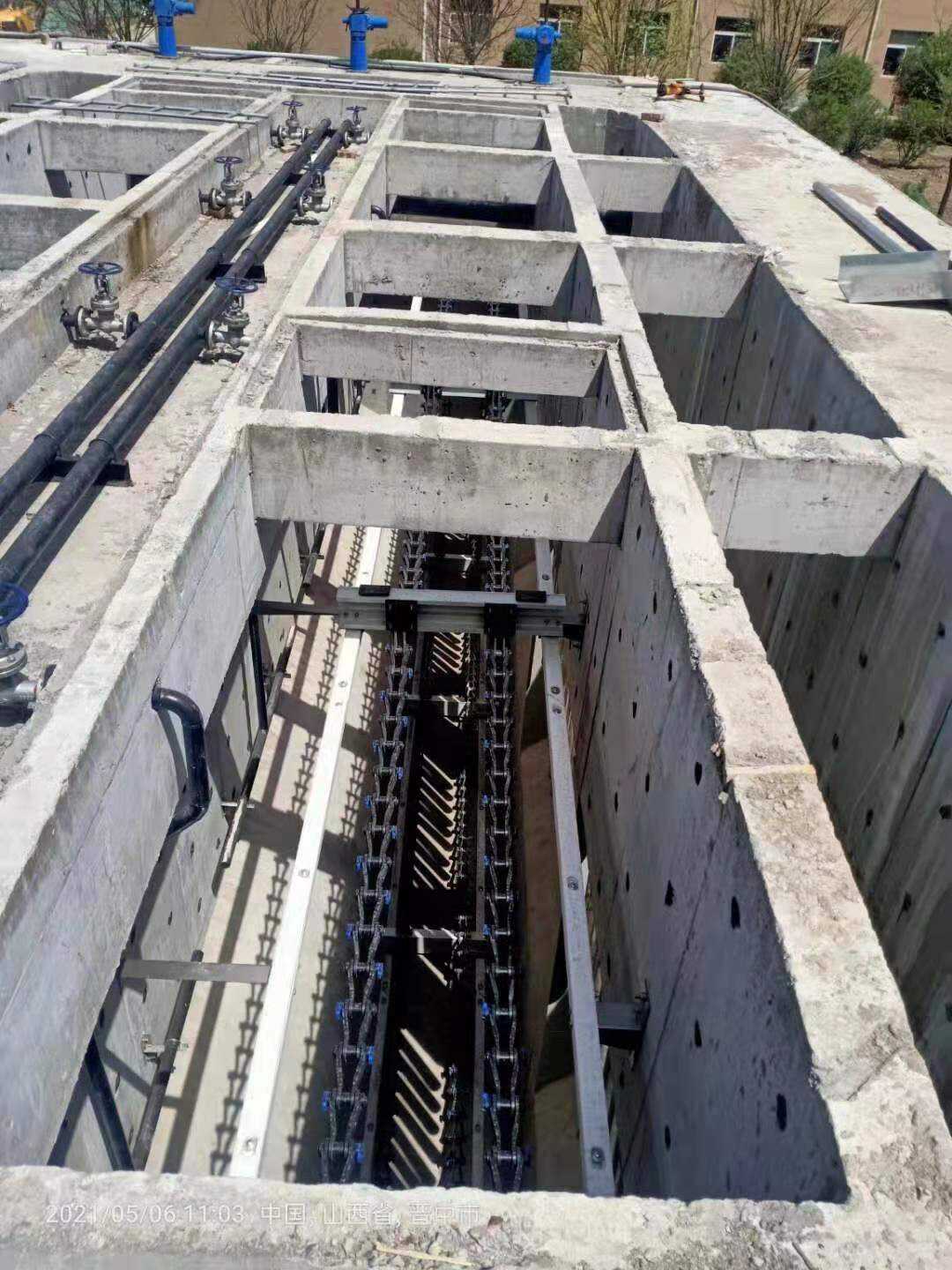

Developing a long-term reliable sewage treatment plant includes the selection of pieces of equipment and other materials that will be reliable for long periods of time without failure. It also involves the consideration of lifetime operational costs and uptime rather than the purchase costs and operational expenses. In these cases, the purchase expenses must be high, for the other operational costs will be high, because the equipment must be able to perform reliably in the highly corrosive and abrasive conditions of wastewater. In this sense, the sludge collection system on the bottom of the sedimentation tank is the most important. If this system fails, the plant will have suffered a catastrophic failure in treatment. Huake provides non-metallic sludge scrapers which, in this context, are aimed for collection systems. They are extremely reliable. Huake scrapers are made from advanced composites, and as a result, are corrosion proof. This also reduces the operational maintenance costs of these scrapers, which is always a fine target to hit. It reduces the scrubber technological failure point that adds to operational maintenance costs. This makes Huake scrapers a truly unique and absolutely strategic choice for a municipality or utility that is expected to end its operational life in 30 or 40 years. These scrapers provide all the operational reliability the primary clarifiers require to operate optimally. It prevents the downstream biological systems from overloaded shock loads and safeguards effluent quality.Essentially, Huake Technology, at its most fundamental, offers a set-it-and-forget foundation for automated sedimentation, a key feature of a genuinely reliable, long-term wastewater treatment plant.