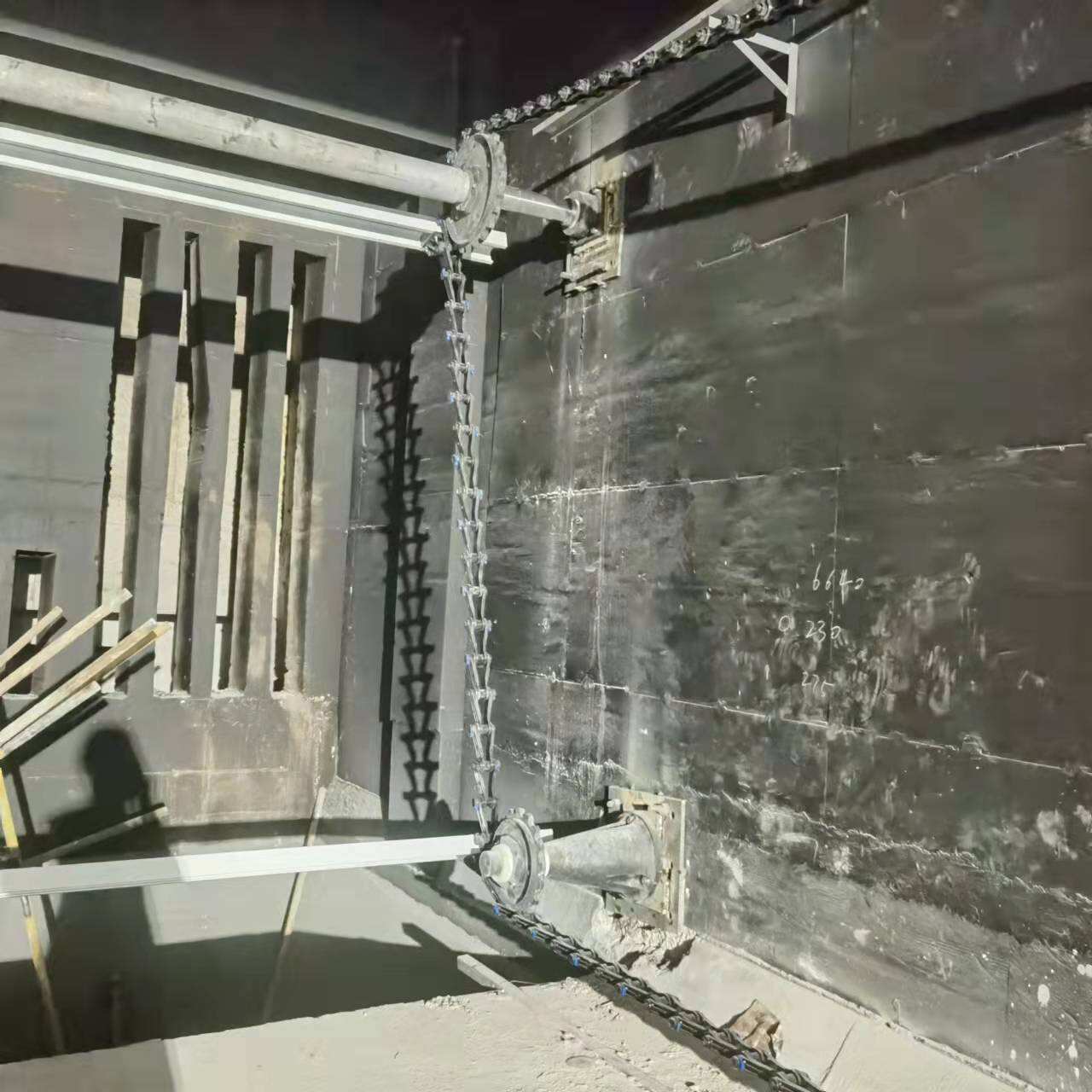

The design of an industrial wastewater treatment plant is very particular, as it is meant to receive and treat process effluent from an industry like manufacturing, chemicals, mining, and others. This wastewater usually contains high concentrations of particular pollutants, extreme pH values, toxins, heavy metals, and complex organics that are not typically found in municipal sewage. Because of this particularity, the design and the selection of equipment is tailored to these plants' treating capabilities. The treatment train often comprises distinct combinations of physicochemical and biological treatment processes. Some of the physicochemical processes include precipitation, various forms of oxidation, advanced oxidation processes, and membrane processes. Furthermore, sedimentation is an important unit process in the treatment train that removes suspended solids after chemical addition or biological flocculation as a separate step. In these very harsh environments, common equipment deteriorates very quickly. For these plants, Huake delivers a very important supply: corrosion resistant non metallic sludge scrapers for the sedimentation units. For example, in the treatment plant of a plating factory where the wastewater is composed of some acids and heavy metals, a conventional metal scraper would corrode quite rapidly, thereby contaminating the sludge and causing the need for frequent cleaning. In a Huake non-metallic scraper, corrosion is not an issue. This ensures operational reliability, steady process efficiencies, and a high quality permanently fixed sludge that is easy to dispose of.A concentration on durability and resilience to wear and chemical corrosion must be aligned to obtain sustainable compliance from industrial plants in meeting rigid discharge limits, diminishing hazardous waste emissions due to equipment failures, and controlling operational expenditures over prolonged periods.