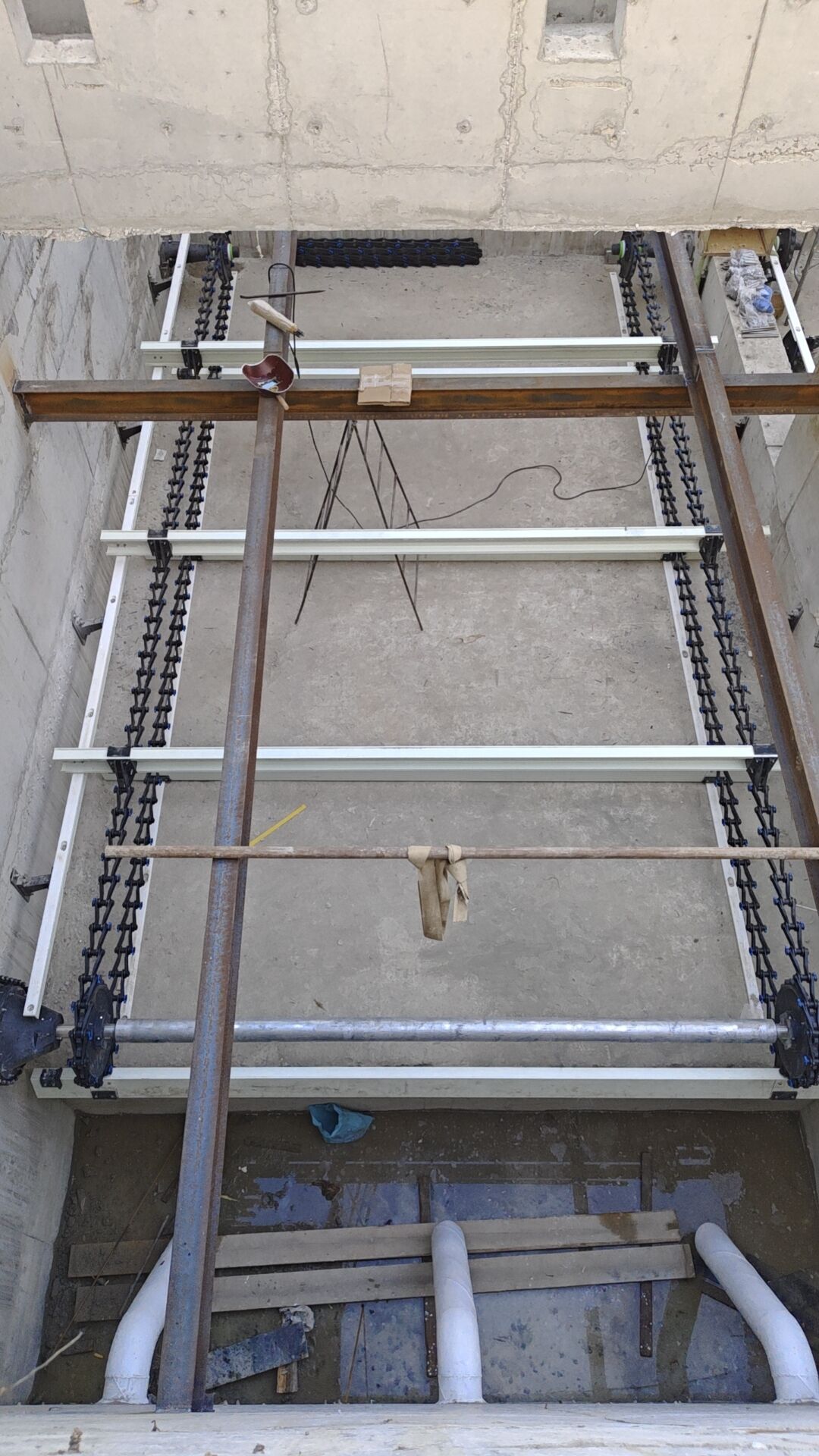

A mud scraper is a fundamental piece of mechanical equipment designed for the continuous removal of accumulated settled solids from the floors of sedimentation tanks and clarifiers. These systems are pivotal in both water and wastewater treatment processes, ensuring that the separation of solids from liquid is efficient and continuous. Mud scrapers are engineered in various configurations, such as chain-and-flight for rectangular tanks or rotating bridge-and-arm for circular units, but all share the common goal of transporting sludge to a collection hopper. The operational environment is exceptionally harsh, characterized by constant immersion, abrasive particles, and often corrosive chemicals or biological agents. Huake specializes in the production of non-metallic mud scrapers that excel in these conditions. By utilizing composite materials with high strength-to-weight ratios and innate corrosion resistance, Huake's scrapers eliminate the common pitfalls of rust, galvanic corrosion, and chemical degradation associated with carbon steel or even stainless-steel alternatives. This results in a product with unparalleled longevity and minimal lifetime maintenance requirements. For example, in a municipal wastewater treatment plant's primary clarifier, the mud scraper operates 24/7, collecting raw sewage sludge. The implementation of a Huake non-metallic mud scraper guarantees decades of reliable service without the need for costly repairs or premature replacement of components, directly translating to lower operating costs, reduced downtime, and a more stable sedimentation process for the entire facility.