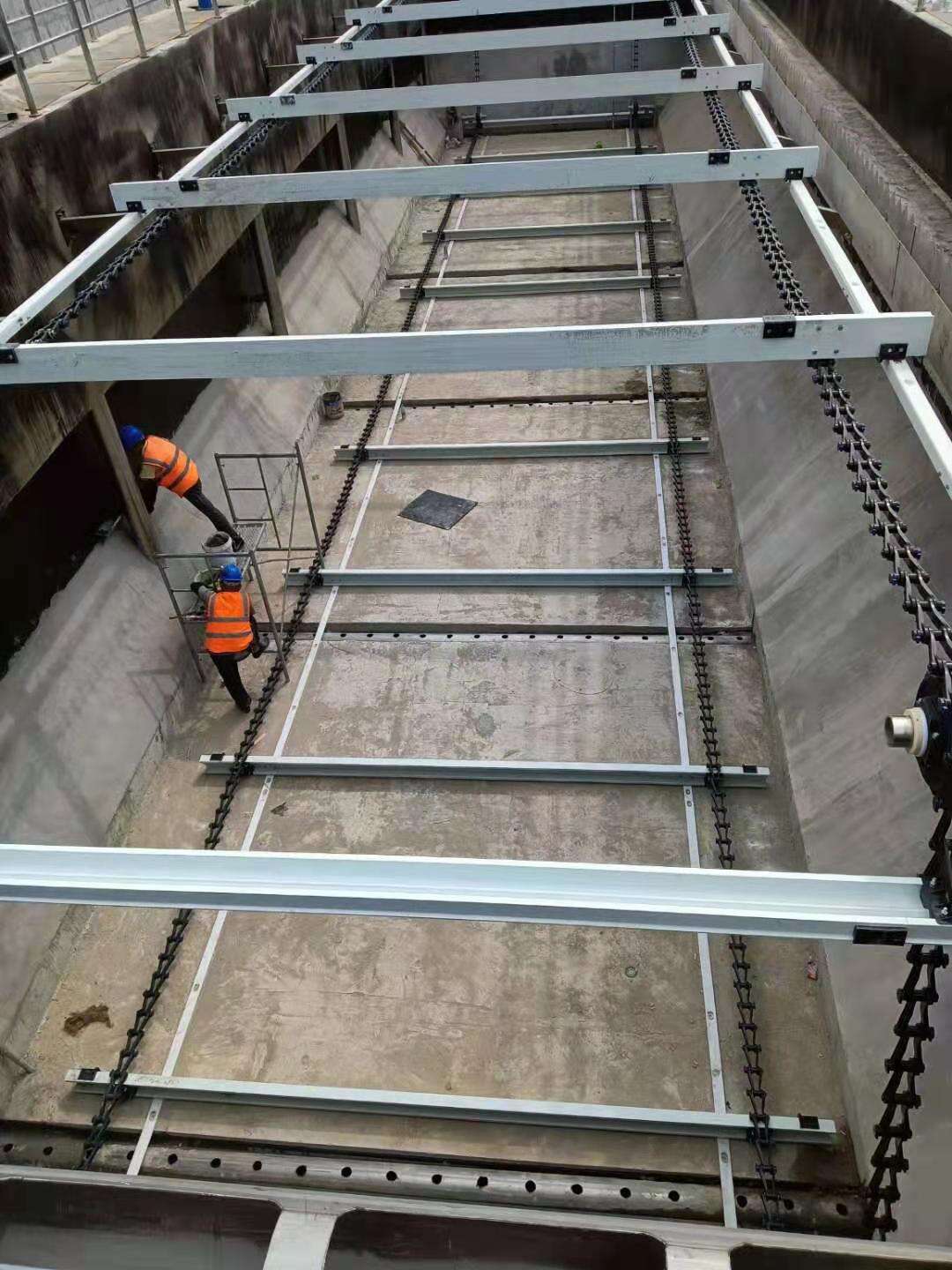

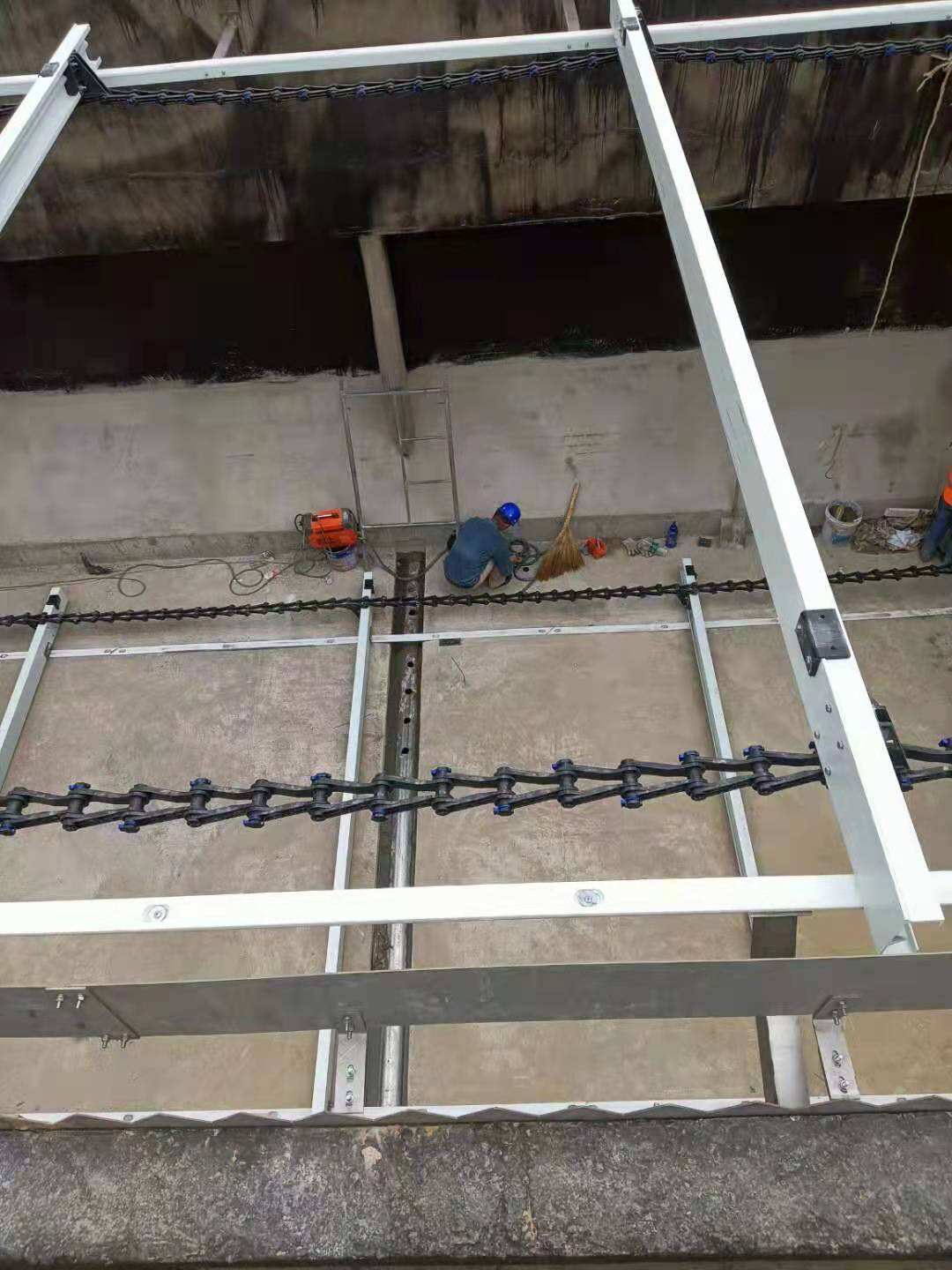

The Mud Scraper is a fundamental and critical component within a Sewage Treatment Plant, specifically located in the primary sedimentation tanks. Its primary function is the continuous and efficient collection of settled raw sludge from the bottom of the clarifier and its conveyance to a hopper for pumping to subsequent treatment stages. The performance of this scraper directly impacts the entire plant's efficiency; ineffective scraping can lead to sludge buildup, septic conditions, increased BOD/SS load on secondary treatments, and potential non-compliance with discharge permits. Therefore, reliability, durability, and consistent performance are paramount. Modern scrapers for sewage plants are designed for heavy-duty operation, constructed from materials that resist corrosion from hydrogen sulfide and other sewage constituents. They feature robust drive mechanisms with adequate torque to handle variable sludge densities and potential obstructions. Many are equipped with automatic torque control and alarm systems to prevent damage from jamming. In a typical municipal plant, these scrapers operate continuously for years with minimal but scheduled maintenance, forming a silent, reliable workhorse of the liquid treatment process. Selecting a scraper designed for the specific hydraulic and solids loading of the plant is crucial for optimal performance. We offer a range of scraper systems engineered for the demands of modern sewage treatment. Contact us to ensure your primary sedimentation process is equipped with the most reliable technology.