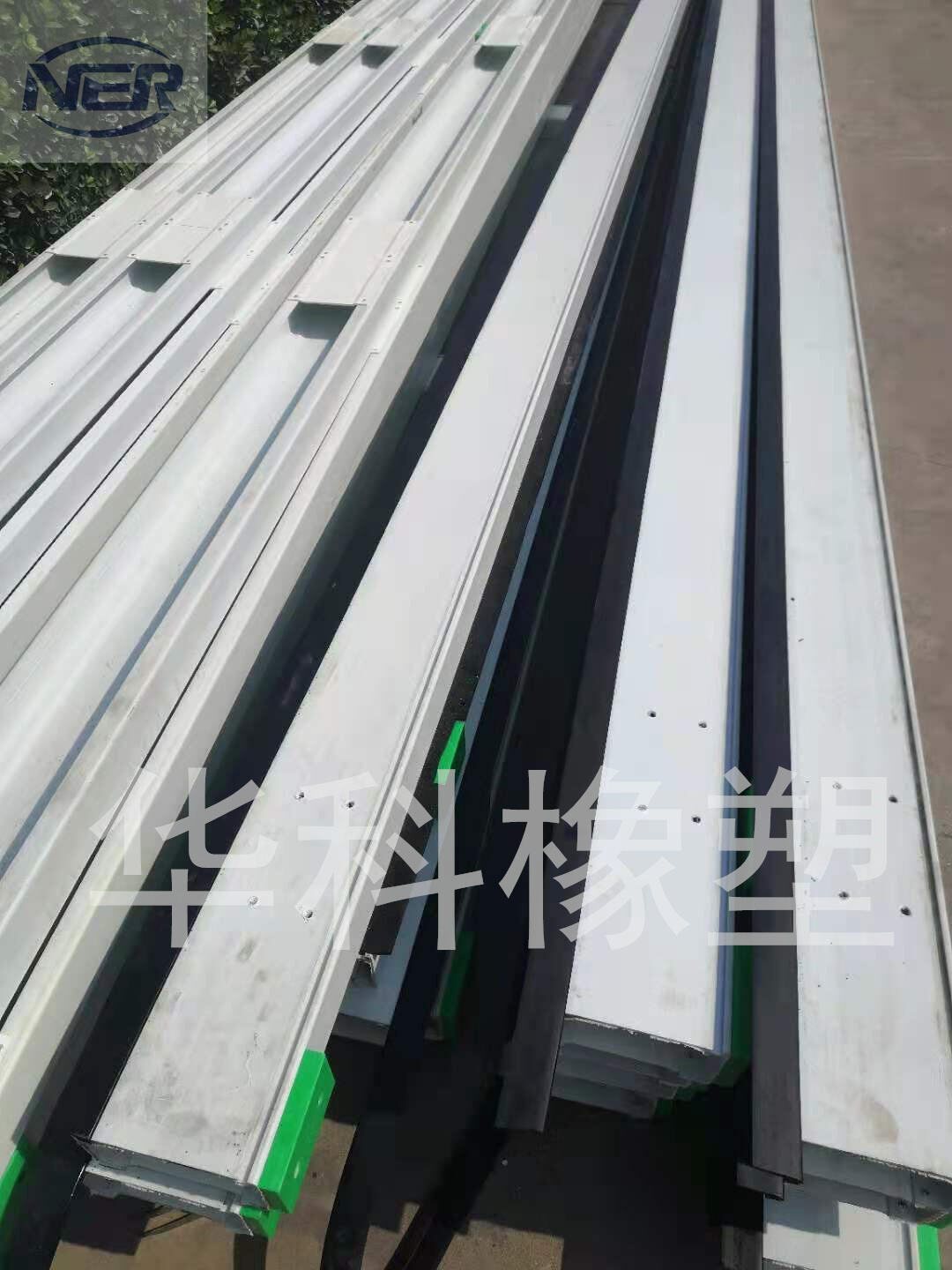

The primary sedimentation tank mud scraper is a heavy-duty system designed for the first stage of solids removal in a wastewater treatment plant. Its role is to continuously collect the raw, settleable solids and scum from the influent sewage before it proceeds to biological treatment. The sludge in this stage is typically dense, abrasive (containing grit and sand), and often corrosive due to the fresh sewage's potential to release hydrogen sulfide. Therefore, the primary scraper must be exceptionally robust. In circular tanks, it consists of a driven bridge with arms that drag plough-like blades along the tank floor. In rectangular tanks, a chain and flight system is used. The key design challenges are preventing grit accumulation under the blades, resisting the abrasive wear, and overcoming the high torque required to move the thick sludge. Modern primary scrapers increasingly use non-metallic materials for flights and wear shoes to combat corrosion and reduce wear. The efficiency and reliability of the primary sedimentation tank mud scraper are critical as it significantly reduces the organic load on the downstream biological reactors, directly influencing their size, energy consumption for aeration, and overall process stability. Effective primary scraping is a fundamental step in ensuring the cost-effective and reliable operation of the entire treatment plant.