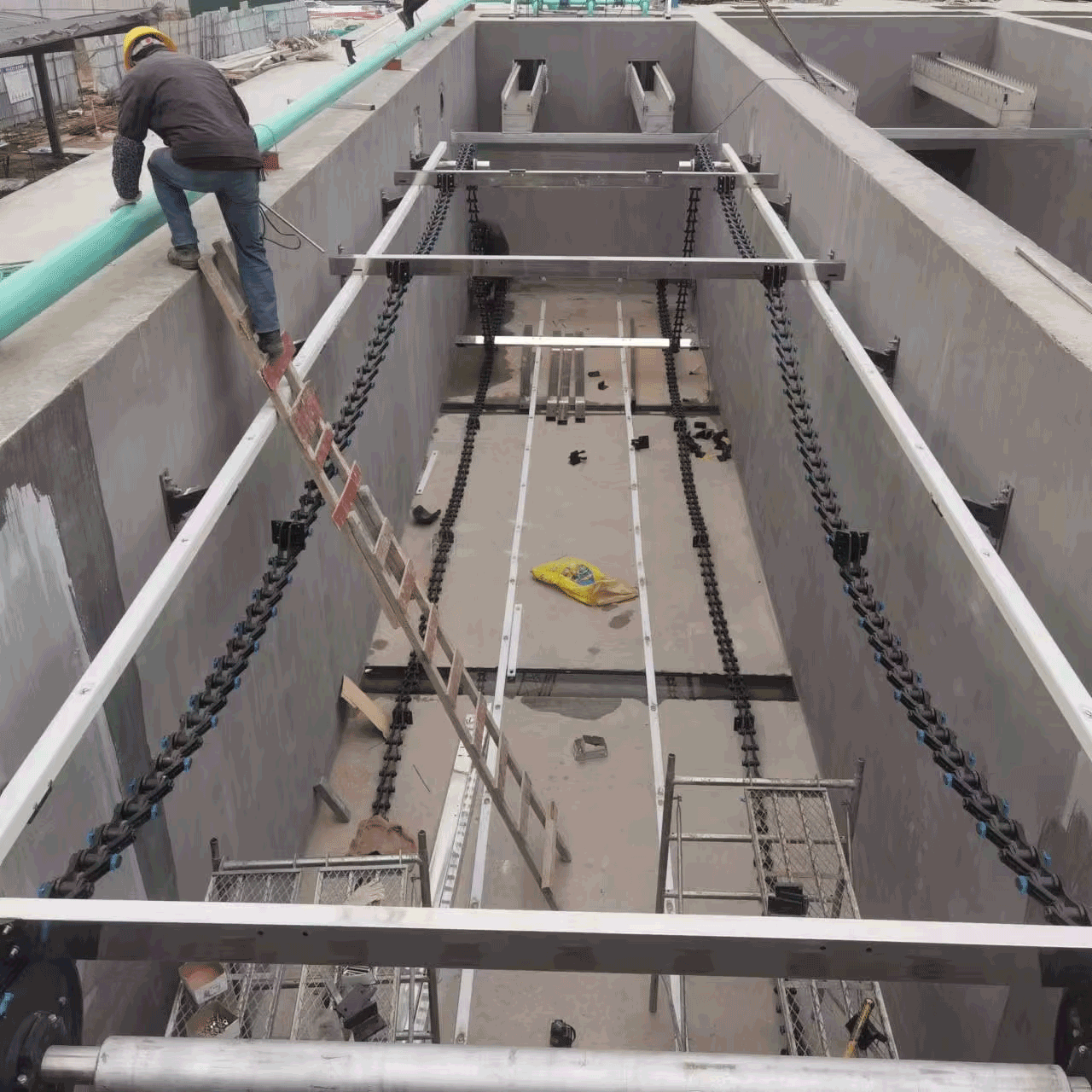

Istilah \"instalasi pengolahan drainase\" umumnya digunakan untuk menggambarkan fasilitas yang mengelola limpasan air permukaan, yang disebut air hujan, atau campuran antara air hujan dan air limbah. Berbeda dengan instalasi pengolahan limbah konvensional yang influennya terutama berasal dari limbah domestik dan industri, instalasi pengolahan drainase harus menghadapi laju aliran dan beban kontaminan yang sangat bervariasi akibat hujan lebat. Instalasi ini harus dilengkapi infrastruktur dan permesinan yang memadai untuk menahan serta mengatasi masuknya air dan puing secara tiba-tiba. Proses-proses yang diterapkan berfungsi untuk mengolah air dengan menghilangkan polutan seperti padatan tersuspensi, hidrokarbon, logam berat, dan nutrisi melalui pemisah minyak-air, filtrasi, dan resonansi. Sebelum air dilepaskan, terdapat badan penerima air. Komponen utama dalam sistem ini adalah tangki atau bak pengendapan. Pengumpulan lumpur secara efisien merupakan komponen penting dalam proses ini. Di sinilah Scraper Lumpur Non-Logam Huake beroperasi. Scraper ini memiliki kualitas luar biasa dan tahan korosi. Scraper dirancang untuk bekerja di bak-bak yang mungkin mengalami perubahan ekstrem pada level air serta mengandung sedimen abrasif dan bahan korosif yang berasal dari jalan raya dan kawasan industri. Di area lumpur dan sedimen dasar yang abrasif, scraper Huake beroperasi secara efisien. Pemasokan scraper Huake ke fasilitas pengolahan drainase di sebuah kawasan industri menjadi contoh nyata. Scraper ini mengendapkan lumpur dan kontaminan, melakukan ini setelah hujan lebat dan bekerja mencegah penumpukan material yang dapat menyumbat tangki dan memperlambat proses pengolahan. Hal ini menjamin bahwa fasilitas tidak melebihi parameter pembuangan lingkungan, melindungi badan air setempat dari pencemaran, serta memerlukan manajemen yang hampir terus-menerus, meskipun dalam kondisi aliran yang sulit dan bervariasi.