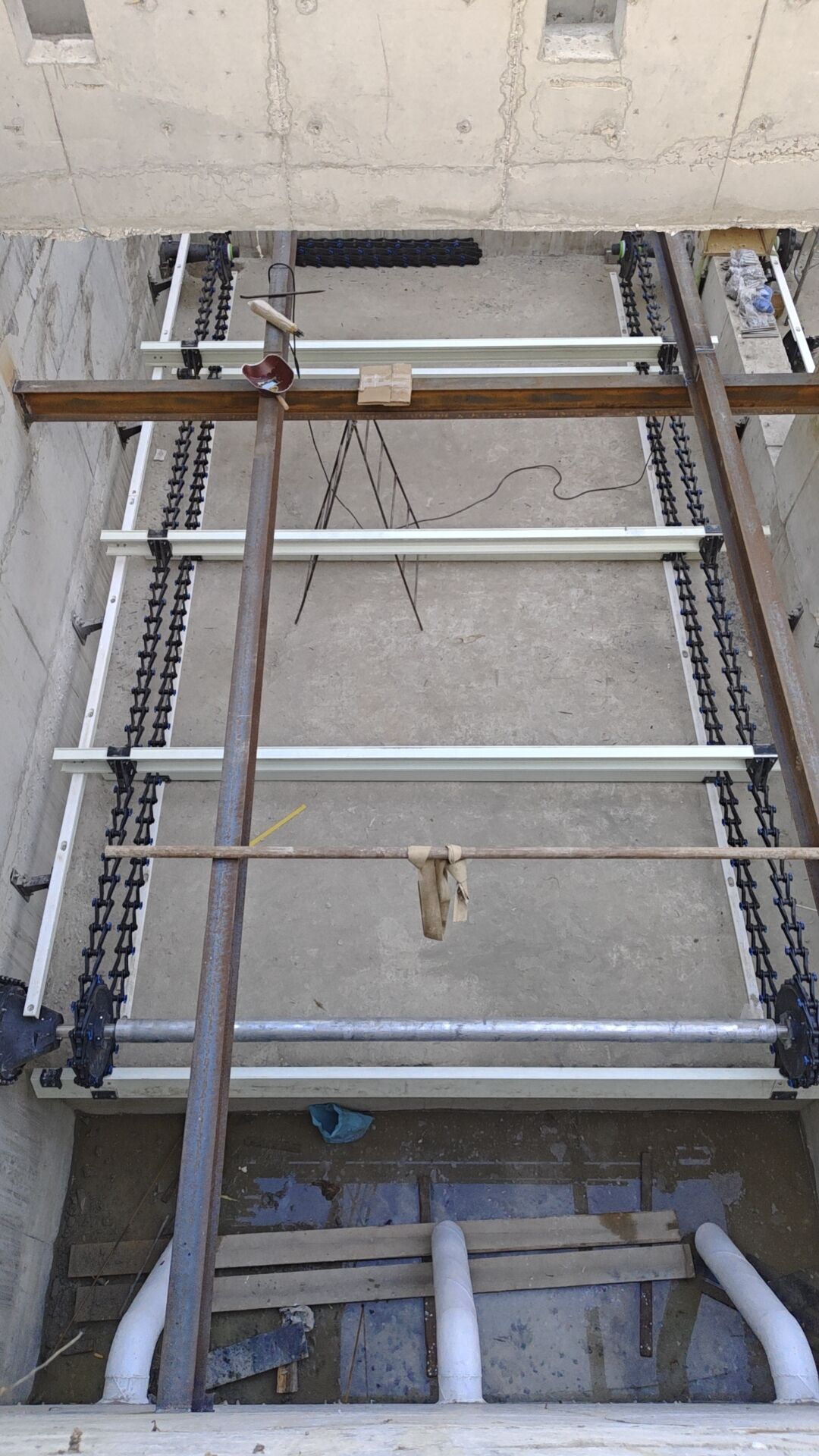

Scraper-type sludge scraping equipment is a broad category of mechanisms that use rigid or flexible blades (flights) to physically push and guide settled sludge along the bottom of a sedimentation tank. This category is defined by the direct mechanical action of a blade in contact with the tank floor, distinguishing it from other methods like suction or vacuum removal. The most common incarnations are the flying scraper (for rectangular tanks) and the circular clarifier with rotating scrapers (for circular tanks). Within rectangular tanks, the scraper-type equipment can be further classified by its drive method: chain-and-flight systems where endless chains drag flights along the bottom, or traction-driven systems where a moving bridge pulls the flights. The design of the scraper blade itself is critical; it must be durable to withstand abrasion, corrosion-resistant to survive the chemical environment, and shaped to effectively move the sludge without causing excessive wear on the tank floor or itself. The blade's bottom edge often incorporates a replaceable wear strip, typically made of a low-friction, durable material like UHMW-PE, to protect both the flight and the tank substrate. The angle of the blade and its height are calculated based on the sludge's angle of repose and expected volume. This type of equipment is renowned for its simplicity, mechanical efficiency, and effectiveness across a vast range of sludge consistencies. It is the most widely adopted technology for primary sedimentation in both municipal and industrial applications. The specific selection of a scraper-type system depends on factors like tank dimensions, sludge load, and available maintenance resources. To discuss the various scraper-type options available for your project and to determine the most suitable and cost-effective solution, please contact our technical sales representatives for expert guidance.