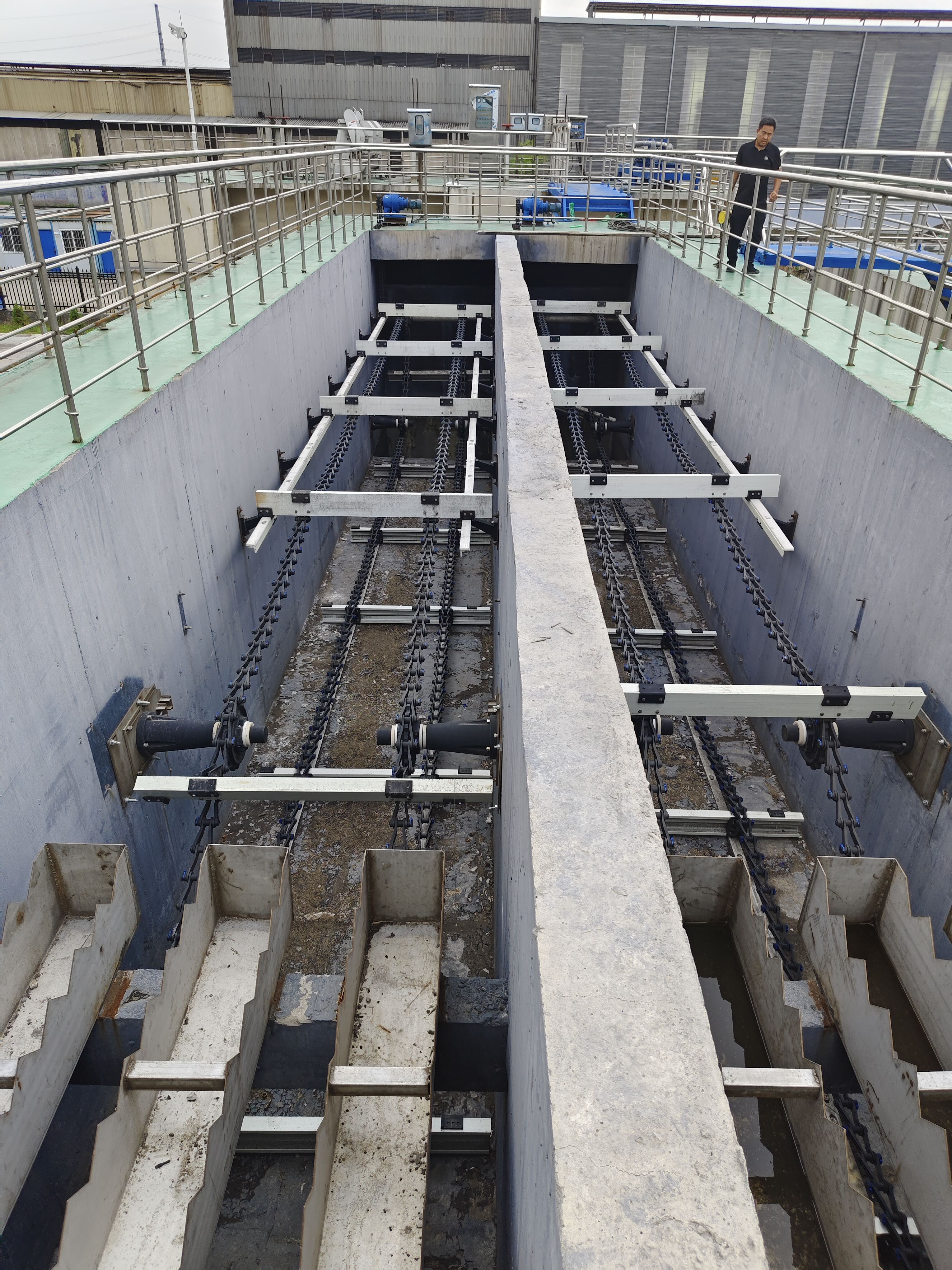

A sludge scraping and collecting system is an integrated solution that encompasses not only the mechanism for moving settled solids along the tank floor but also the means of efficiently elevating and transferring them out of the sedimentation basin for further treatment. This holistic system is crucial for the complete automation of the sludge handling process. The scraping component, typically a flying scraper or chain-and-flight system, is responsible for consolidating the sludge. The collection component usually involves one or more sludge hoppers (or pits) located at the end of the tank. The critical interface is how the scraper efficiently directs the sludge into these hoppers. The scraper flights are designed to create a positive sweeping action that pushes the sludge up an inclined ramp or directly into the hopper opening without allowing significant spillback. From the hopper, the collected sludge is typically removed by positive displacement pumps (e.g., progressive cavity pumps) or by gravity through large-diameter pipes, often assisted by sludge pumps or ejectors. The entire process is often controlled by a programmable logic controller (PLC) that synchronizes the scraper movement with the pump operation, often based on level sensors in the hopper to prevent pump dry-running or overflow. In a large water treatment plant, this integrated system ensures that the clarified water overflow weirs remain uncontaminated by settled impurities, directly impacting the quality of the finished water. The efficiency of the entire sedimentation process hinges on the reliability of this scraping and collecting system. A well-designed system minimizes the water content of the collected sludge (through effective compaction on the tank floor) and ensures its prompt removal, preventing septic conditions. For a comprehensive solution that includes both scraping and efficient collection, we invite you to contact our engineering team to design a system optimized for your tank geometry and sludge characteristics.