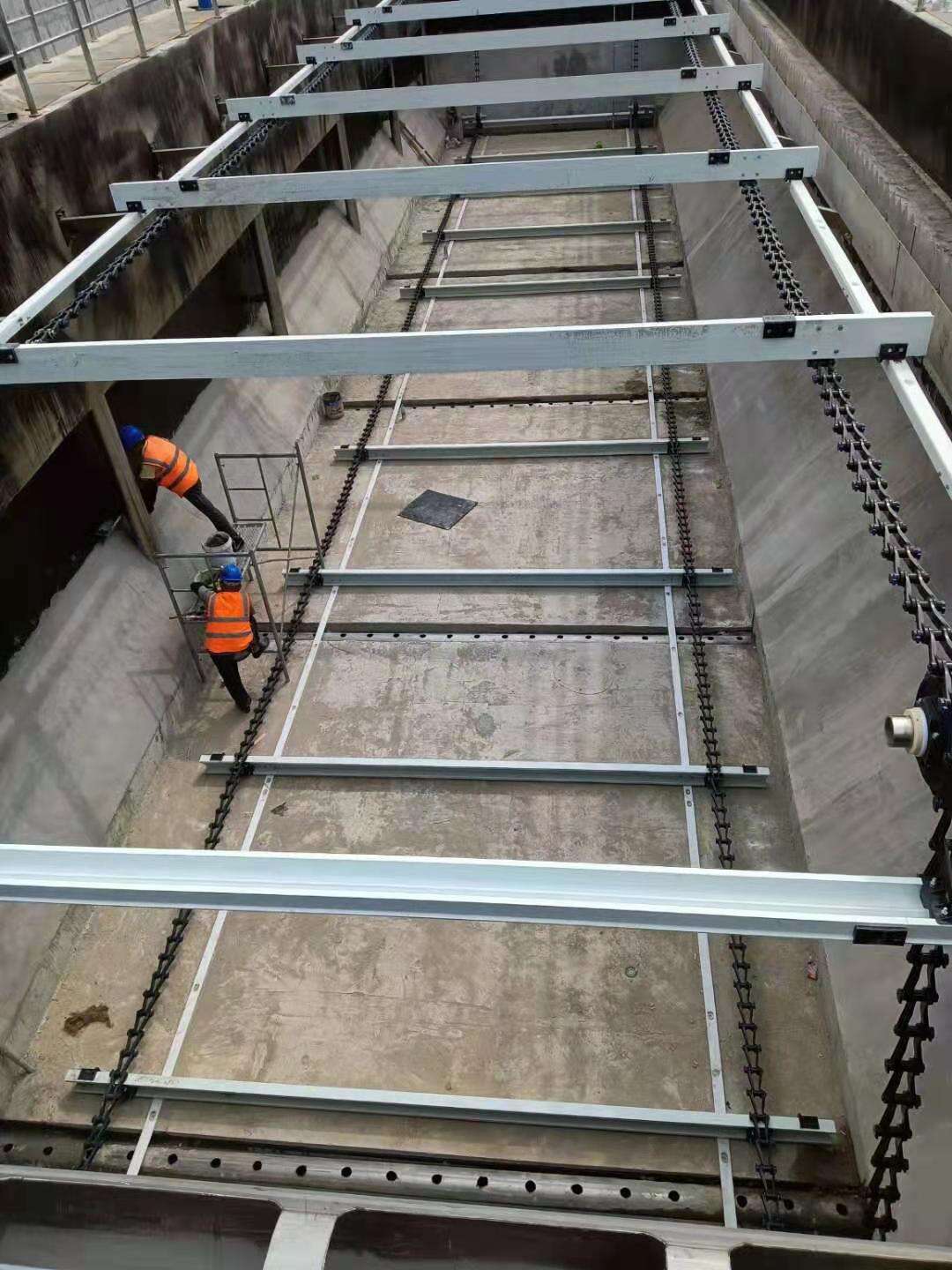

Environmental protection scraper systems are critical components within modern wastewater treatment infrastructure, engineered to efficiently remove settled sludge and scum from sedimentation basins without disrupting the delicate biological and chemical processes essential for purification. These systems directly contribute to environmental protection goals by ensuring the consistent and reliable operation of treatment plants, which in turn safeguards water quality in receiving rivers, lakes, and oceans. The application of advanced, corrosion-resistant non-metallic materials in their construction is paramount, as it prevents the introduction of metallic contaminants into the treated water and ensures longevity despite constant exposure to highly abrasive and chemically aggressive sewage. A typical application scenario involves a municipal wastewater plant where the scraper system continuously operates, collecting settled organic matter from the bottom of large circular or rectangular clarifiers. This collected sludge is then processed further in digesters to produce biogas, a renewable energy source, turning waste into value. The high stability and low-maintenance design of these systems are crucial for minimizing operational downtime and energy consumption, thereby reducing the overall carbon footprint of the treatment facility. For communities and industries committed to sustainable water management and regulatory compliance, investing in a robust environmental protection scraper system is not an option but a necessity for long-term operational success and ecological responsibility.