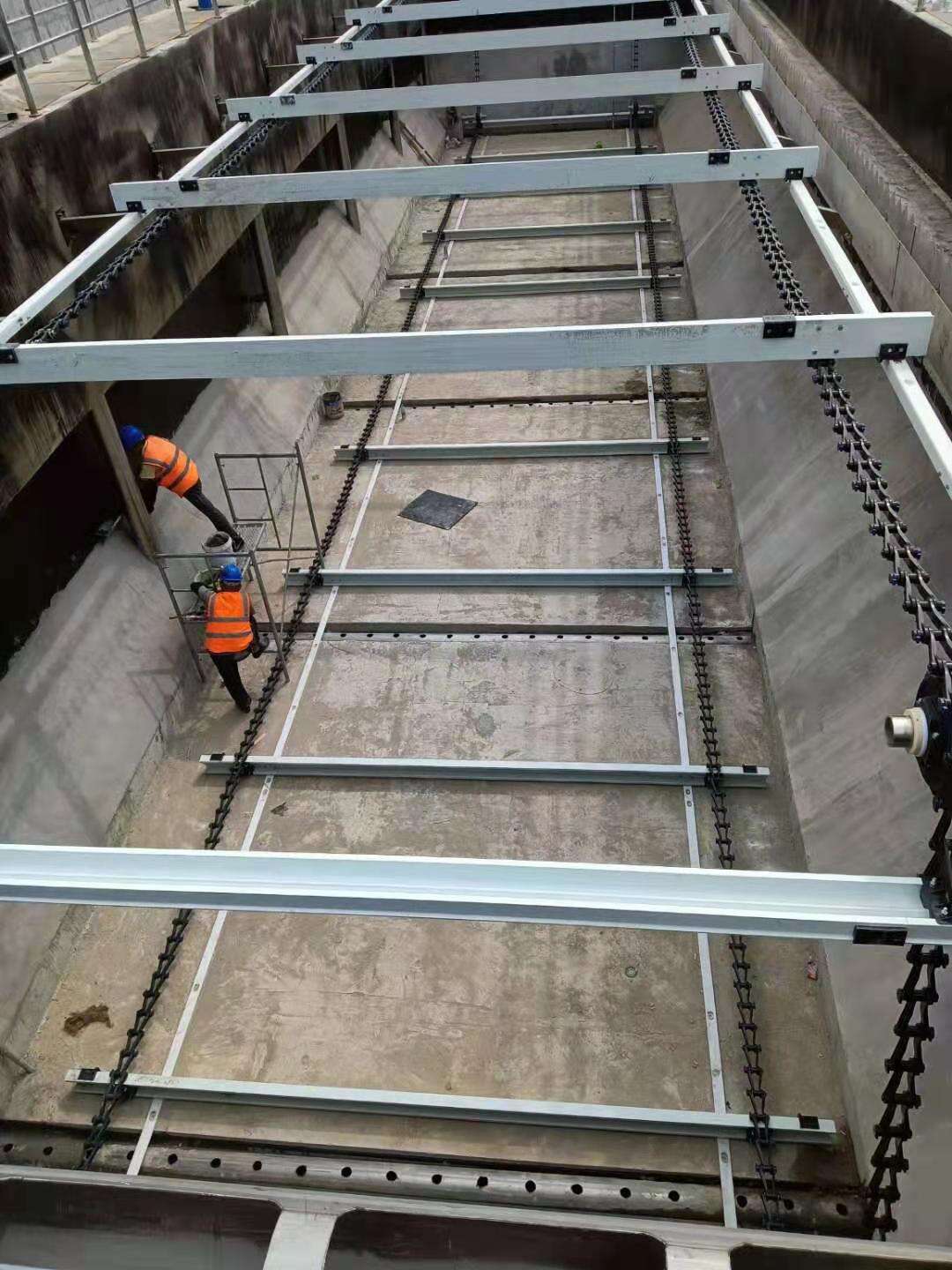

A non-metallic chain wheel scraper system represents a significant engineering advancement in sedimentation tank technology, utilizing high-performance polymers or composite materials for the entire drive train, including the chain, sprockets (chain wheels), and flight supports. This design fundamentally eliminates the most common failure points found in traditional steel systems: corrosion, galvanic coupling, and excessive wear. The non-metallic chain wheel assembly operates smoothly without the need for constant lubrication, drastically reducing maintenance demands and preventing oil contamination of the wastewater. In a harsh application scenario, such as an industrial wastewater treatment plant handling high-chloride or acidic effluent, a steel system would rapidly deteriorate, leading to frequent breakdowns and costly replacements. In contrast, a non-metallic system withstands the corrosive environment, ensuring continuous, reliable sludge removal. The inherent lightweight properties of the materials also contribute to lower energy consumption for the drive mechanism. The modular nature of many non-metallic chain designs allows for easy replacement of individual components without requiring extensive tank decommissioning, further minimizing downtime. This system is the optimal choice for engineers and plant managers who prioritize long-term asset integrity, reduced total cost of ownership, and uncompromised performance in chemically challenging sedimentation processes.