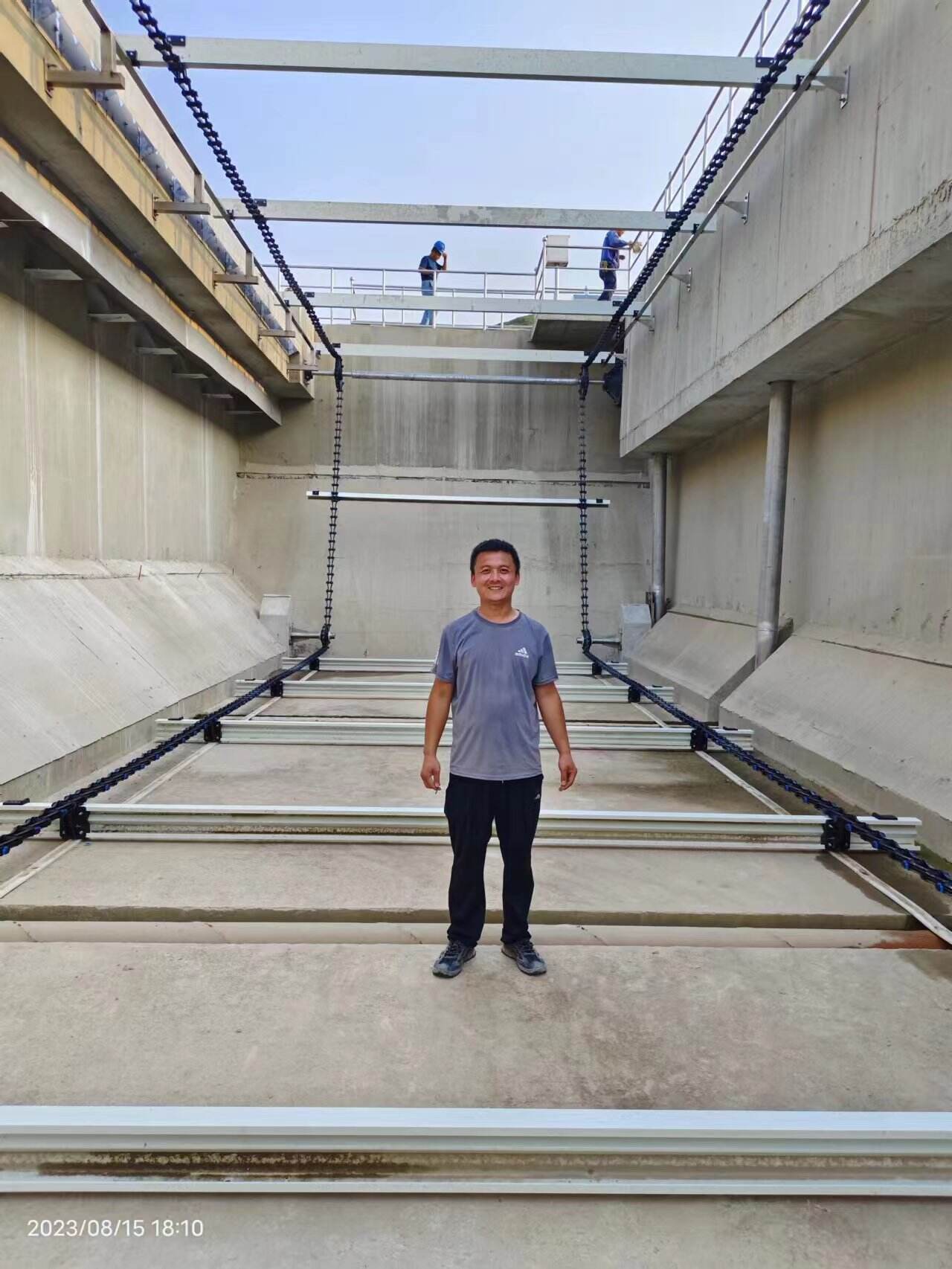

A lightweight modular scraper system is designed for ease of installation, simplified maintenance, and future adaptability. Constructed primarily from high-strength, non-metallic composites and polymers, the system offers a significant weight reduction compared to traditional steel-based systems. This lightweight nature translates into multiple benefits: it reduces the structural load on the tank walls and bridge, allows for use of smaller and more energy-efficient drive units, and makes handling during installation or component replacement much easier and safer, often without the need for heavy lifting equipment. The modular design philosophy means that key components, such as individual flight segments, chain links, or wear shoes, are standardized and can be quickly unbolted and replaced without dismantling large sections of the system. This dramatically reduces downtime during maintenance operations. In a scenario where a specific flight is damaged, a plant maintenance crew can replace that single module in hours instead of taking the entire tank out of service for days for major repairs. This approach is particularly advantageous for older plants undergoing upgrades or for installations in remote locations where specialized labor and equipment are scarce. The modularity also offers flexibility, allowing the system to be adapted or extended if the tank configuration changes in the future. This design prioritizes life-cycle cost savings, operational resilience, and long-term convenience for the plant operator.