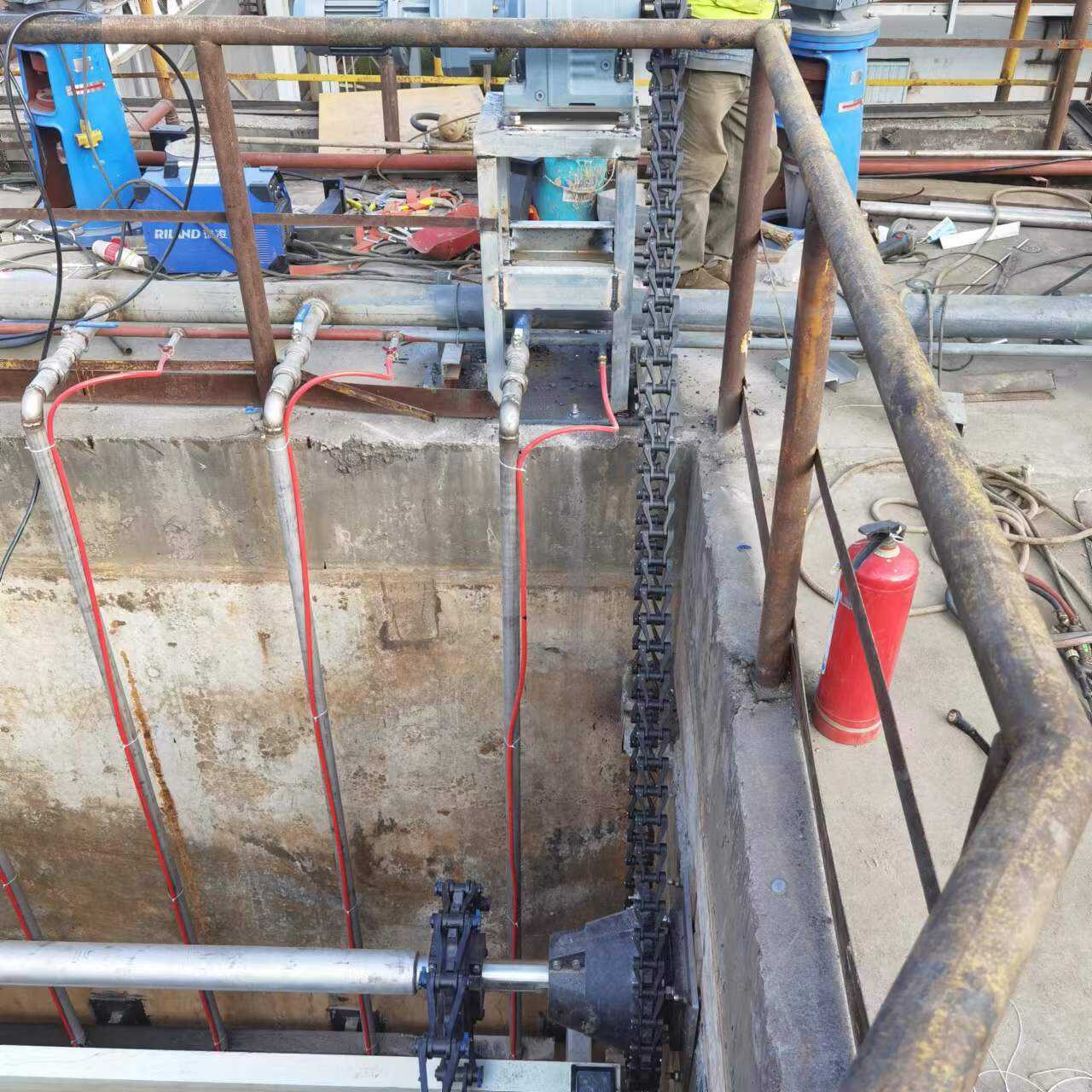

A rectangular tank scraper system, most commonly a chain and flight collector, is a workhorse design for primary sedimentation, equalization, and cooling water basins in water and wastewater treatment plants. Its linear configuration is ideal for sites where space utilization favors long, rectangular concrete tanks often built in parallel. The system consists of two endless chains running on sprockets at each end of the tank, with crossbars (flights) attached that scrape the bottom and skim the surface as they are pulled by the chains. The drive unit is typically located at the effluent end. The key advantages of this design include a large effective settling area and a proven, robust mechanical principle. Modern advancements have focused on enhancing the durability and reducing the maintenance of these systems. This includes the adoption of non-metallic chains and flights that are immune to corrosion and offer superior wear resistance, outlasting steel in abrasive conditions. In a large municipal plant, multiple rectangular tanks with chain and flight scrapers can operate continuously for years, reliably collecting raw sludge. The modular design of many contemporary systems allows for individual flight or chain segment replacement without dewatering the entire tank, a significant operational advantage. While requiring more mechanical components than a circular scraper, the rectangular tank scraper system remains a highly effective and widely adopted solution for numerous sedimentation applications worldwide.