Understanding Scraper Stability: Role, Design Principles, and Real-World Failures

The critical role of scraper systems in continuous sedimentation basin operation

Scraper systems keep sedimentation tanks running smoothly day after day, making sure sludge gets removed reliably during those constant wastewater treatment operations. Without these mechanical setups, solids tend to build up past the critical 40 cm mark where raw biomass starts slipping through secondary clarifiers uncontrollably. The scrapers work best when moving at just the right speed range between 0.03 and 0.06 meters per second. At this pace, most plants report capturing around 98% of the solids floating around down there. Plus, operators find that running them this way actually saves on electricity costs without sacrificing performance.

How structural integrity influences scraper stability under dynamic operational loads

During peak flow conditions, scraper components face 2—4 times baseline stress. To withstand these dynamic loads, engineers implement key design strategies:

- Twin-beam construction: Distributes bending moments across parallel girders to reduce localized stress

- Fail-safe drive couplings: Protect motors from burnout during debris obstructions

- Modular joint assemblies: Enable targeted repairs without full system shutdown

Material choice plays a decisive role—ASTM A572 Grade 50 steel has demonstrated 32% higher fatigue resistance than standard carbon steel in five-year field studies, significantly enhancing long-term durability.

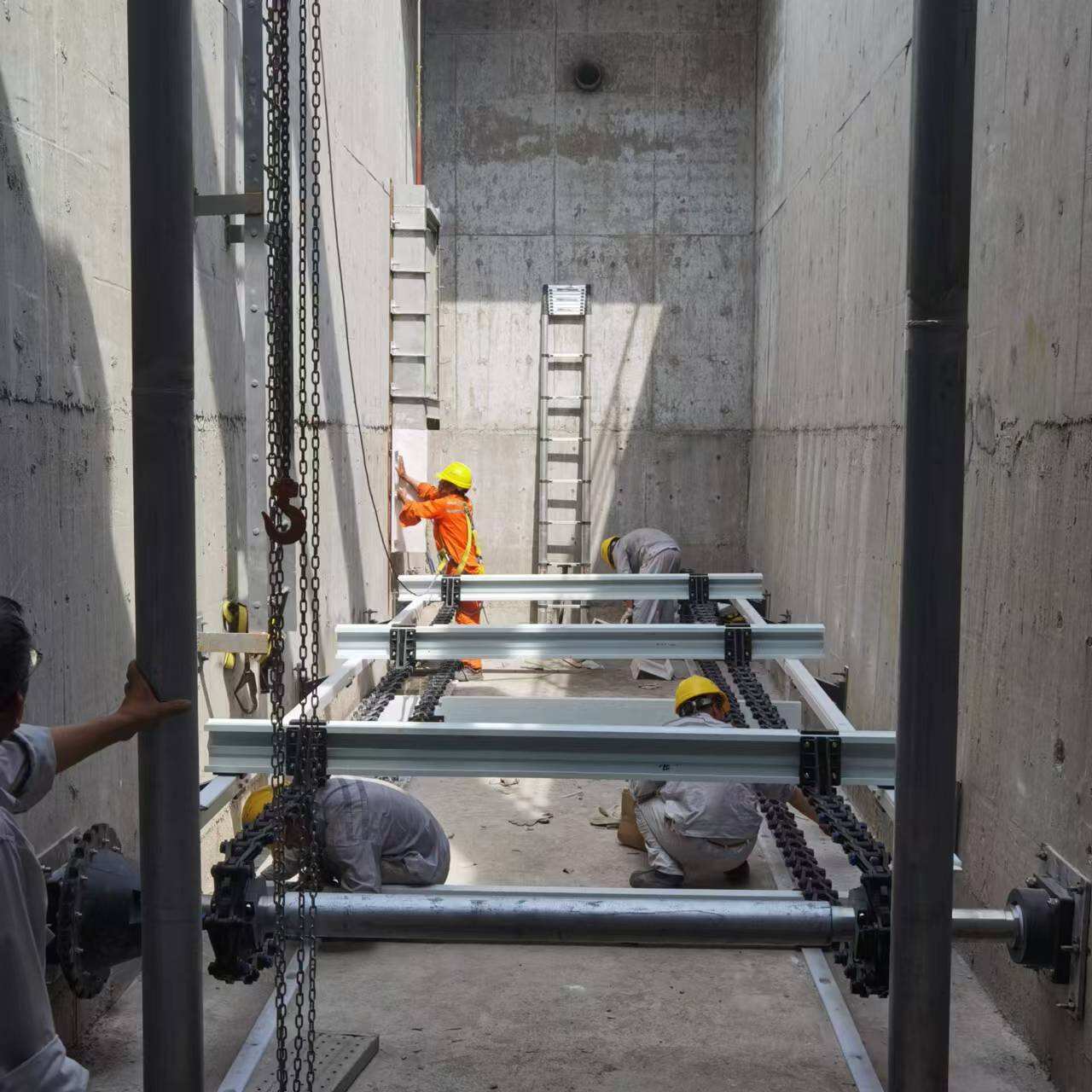

Case study: Analyzing scraper failures in municipal wastewater treatment plants

A 2023 analysis of 47 municipal plants found that chain-driven scrapers accounted for 78% of maintenance incidents, with chain component failures representing 21.5% of total downtime. Hydrogen sulfide (H‚S) concentrations exceeding 50 ppm accelerated corrosion, reducing stainless steel chain service life by 42% compared to glass-reinforced polymer alternatives.

Corrosion-Resistant Materials for Long-Term Scraper Stability

Key materials: Duplex stainless steel and GRP in mud scrapers for harsh environments

Today's scraper systems are built using materials that balance durability with protection against rust and chemical damage. Duplex stainless steel stands out as the go-to material for parts that need to handle heavy loads, since it can stand up to chloride concentrations as high as 5,000 ppm without breaking down. For areas where sulfides are common, Glass Reinforced Plastic (GRP) performs exceptionally well. Tests show that even after sitting underwater for five years, GRP keeps about 85% of its original strength according to standard industry tests. Many manufacturers now combine these materials smartly in their designs. They apply GRP where it touches process media while using the stronger duplex steel for framework and support structures. This approach cuts down on wear and tear by roughly half compared to older carbon steel systems, which means longer equipment life and fewer maintenance headaches.

Degradation mechanisms: Chemical pitting, galvanic corrosion, and stress corrosion cracking

Corrosion-induced scraper failures typically stem from three primary mechanisms:

- Chemical pitting: Sulfide exposure causes surface erosion at 0.1—0.3 mm/year in standard stainless steel grades

- Galvanic corrosion: Electrical potential between dissimilar metals accelerates deterioration at joints

- Stress corrosion cracking: Combined tensile stress and chloride exposure can fracture 316L stainless steel within five years at temperatures above 60°C

Material performance thresholds guide selection—GRP outperforms metals in highly acidic conditions (pH <3) and high chloride environments (>500 ppm), while duplex steels remain stable in moderate acidity (pH 2—5).

Emerging trend: Non-metallic chain scraper systems in aggressive wastewater conditions

Advancements in polymer technology have led to non-metallic scraper systems with superior durability:

| Performance Metric | Metal Scrapers | Non-Metallic Scrapers |

|---|---|---|

| Corrosion Rate | 0.5—1.2 mm/year | <0.05 mm/year |

| Maintenance Intervals | 50 operating hours | 800+ operating hours |

| Replacement Cycle | 18—24 months | 5—7 years |

Ultra-high molecular weight polyethylene (UHMWPE) blades have proven particularly effective, reducing biofilm adhesion by 70% compared to steel in municipal wastewater applications.

Hybrid scraper designs: Combining stainless steel and non-metallic components for optimal durability

Hybrid systems combine duplex stainless steel frames with GRP scraping parts because they get the best of both worlds metal strength and composite materials that don't react chemically. According to field tests, these hybrid designs actually cut lifecycle costs down by around 32 percent over twenty years when compared to traditional all metal scrapers. What's even better? They slash downtime by nearly 80 percent in those really acidic environments where pH levels drop below 3, according to research from the EPA back in 2022. Another big plus point for these systems is their modular setup. When a GRP blade wears out, technicians can just replace that one part instead of taking apart the whole thing. This makes maintenance much faster and contributes to overall sustainability since fewer resources go into repairs over time.

Mechanical Design Features That Enhance Scraper Structural Stability

FEA-optimized scraper geometry for balanced load distribution and rigidity

Using Finite Element Analysis (FEA) allows engineers to create detailed models of scraper structures that spread out operational stresses more evenly. This technique can cut down on those hot spots of stress by around 40%, which makes a real difference in how long equipment lasts. Systems that have been upgraded with these FEA optimized designs typically last about seven years before needing major repairs or replacement, whereas older models usually need attention every three to five years. The method also strengthens the parts that handle the most weight while keeping other sections flexible enough for movement. In practice, this results in scraper blades distributing loads consistently across their surfaces, with performance ranging from 92% to nearly 97% uniformity even in large tanks measuring up to 45 meters across.

Reinforced cross-members and their impact on long-term scraper integrity

Steel cross members made from box section profiles actually provide about 60 percent more torsion resistance compared to standard I beams. When installed in city infrastructure projects, this reinforcement makes a big difference too, cutting down on structural warping by roughly 83 percent after ten years of use. Recent tests from last year's corrosion research indicate something else important as well. Cross members with special protective coatings plus built in drainage systems last around 22 extra months when exposed to wastewater with high chloride levels (over 1,500 parts per million). Municipal engineers are starting to take notice of these findings for their long term maintenance cost savings potential.

Center drive vs. peripheral drive scrapers: Performance in large-diameter sedimentation tanks

When looking at tanks bigger than 30 meters across, peripheral drive systems actually need about 18 to 24 percent less torque compared to those central drive setups, as found in recent wastewater engineering research from last year. On the flip side, central drives tend to get rid of sludge much quicker in places where they process lots of material, around 35% faster when dealing with flows equal to or above 500 cubic meters per hour. Many newer installations now combine elements from both approaches, creating these hybrid systems that have backup pathways built right in. This redundancy cuts down on unexpected repairs by roughly two thirds in treatment plants that manage over 200 tons of dry solids each day, which makes a big difference for facility managers trying to keep things running smoothly without constant interruptions.

Drive Systems and Operational Load Management for Stable Scraper Performance

Matching Drive Systems (Center, Peripheral, Chain-and-Flight) to Tank Size and Load Requirements

Choosing the right drive system really comes down to two main factors: what shape the tank is and what kind of sludge we're dealing with. Center drives work pretty well for round tanks up to about 25 meters across. They give good balance when handling sludge that's not too thick or heavy. When we get to bigger round tanks, say over 30 meters, peripheral drives become necessary. These systems have gear reducers mounted around the edges which handle those massive chain tensions sometimes going over 12 kilonewtons without bending anything. This matters a lot at treatment plants where daily flow rates exceed 10,000 cubic meters. For those long rectangular tanks stretching beyond 50 meters, chain and flight systems do the job best. They push through the really thick sludge towards the collection area without stirring it back up unnecessarily. Plants that match their drive systems properly to tank sizes report roughly half the unexpected breakdowns compared to facilities where everything just doesn't fit together right according to EPA data from last year.

Balancing Scraper Speed and Solids Re-Suspension to Maintain Process Efficiency and Stability

Variable frequency drives or VFDs let operators adjust scraper speeds as needed when dealing with sludge buildup in real time. Going too fast above 1.2 meters per minute can stir up settled solids again, which nobody wants. On the flip side, if speeds drop below 0.6 m/min, sludge just piles up too much and puts extra stress on all those moving parts. Some systems now combine torque sensors with these VFD controllers, cutting energy costs somewhere between 18 to maybe even 35 percent without sacrificing how well they remove stuff. The stats back this up too. About 8 out of 10 facilities monitoring their equipment report fewer overload problems since implementing such controls, based on observations across roughly 140 different wastewater treatment sites around the country.

Selection Criteria for High-Stability Scrapers in Wastewater Applications

Lifecycle cost analysis: Initial investment vs. long-term maintenance and downtime savings

Effective scraper selection requires evaluating total ownership costs rather than initial price. Manufacturers now provide 20-year projections showing corrosion-resistant models reduce maintenance expenses by 40—60% compared to carbon steel alternatives. These savings offset higher upfront investments through extended service intervals and fewer sludge removal failures.

Ease of installation and compatibility with existing sedimentation tank infrastructure

Modular scraper systems can be retrofitted into existing basins without structural modifications in 83% of cases, according to wastewater engineering reports. Compatibility hinges on alignment with legacy drive gearboxes and adaptable blade configurations for irregular tank geometries.

Data insight: 78% reduction in downtime using corrosion-resistant, modular scraper systems (EPA, 2022)

According to EPA studies, stainless steel chain scrapers equipped with quick disconnect modules last about 12,000 hours before needing maintenance—that's roughly three times better than what we see with standard models on the market today. The secret lies in how these units are built. They feature specially welded joints designed to handle the constant back and forth motion inside those big tanks at wastewater treatment plants. This engineering makes all the difference when it comes to keeping things running smoothly. Facilities report seeing around a 78 percent drop in unexpected shutdowns since switching to this newer design, which means fewer headaches for plant managers dealing with breakdowns during critical processing periods.

FAQs

What is the ideal speed range for scraper systems in sedimentation tanks?

The ideal speed range for scraper systems in sedimentation tanks is between 0.03 and 0.06 meters per second, which helps in capturing around 98% of solids efficiently.

Why is duplex stainless steel used in scraper systems?

Duplex stainless steel is used because it can withstand high chloride concentrations and heavy loads without deteriorating, making it highly durable in harsh environments.

How do non-metallic scrapers perform compared to metal scrapers?

Non-metallic scrapers have a much lower corrosion rate (<0.05 mm/year) compared to metal scrapers (0.5–1.2 mm/year), offering longer maintenance intervals and replacement cycles.

What are the benefits of hybrid scraper systems?

Hybrid scraper systems combine metal strength with non-reactive composite materials, reducing lifecycle costs by about 32% and downtime by nearly 80% in acidic environments.

How does FEA-optimized geometry improve scraper stability?

Finite Element Analysis (FEA) optimizes scraper geometry, spreading operational stresses more evenly, reducing stress hot spots by 40%, and extending the lifespan of scraper systems.

Table of Contents

- Understanding Scraper Stability: Role, Design Principles, and Real-World Failures

-

Corrosion-Resistant Materials for Long-Term Scraper Stability

- Key materials: Duplex stainless steel and GRP in mud scrapers for harsh environments

- Degradation mechanisms: Chemical pitting, galvanic corrosion, and stress corrosion cracking

- Emerging trend: Non-metallic chain scraper systems in aggressive wastewater conditions

- Hybrid scraper designs: Combining stainless steel and non-metallic components for optimal durability

- Mechanical Design Features That Enhance Scraper Structural Stability

- Drive Systems and Operational Load Management for Stable Scraper Performance

- Selection Criteria for High-Stability Scrapers in Wastewater Applications

-

FAQs

- What is the ideal speed range for scraper systems in sedimentation tanks?

- Why is duplex stainless steel used in scraper systems?

- How do non-metallic scrapers perform compared to metal scrapers?

- What are the benefits of hybrid scraper systems?

- How does FEA-optimized geometry improve scraper stability?